現代的(de)立式穿(chuan)(chuan)(chuan)孔機上(shang)(shang)一般(ban)都配(pei)備完成(cheng)以下(xia)(xia)動(dong)作的(de)輔助機械:(1)在加熱好坯(pi)料的(de)內外(wai)表面上(shang)(shang)涂(tu)敷玻璃潤(run)滑劑(ji);(2)將內外(wai)表面經(jing)潤(run)滑的(de)坯(pi)料從潤(run)滑臺送(song)至穿(chuan)(chuan)(chuan)孔筒(tong)(tong)上(shang)(shang)方的(de)位置;(3)將坯(pi)料及剪(jian)切環送(song)入(ru)穿(chuan)(chuan)(chuan)孔筒(tong)(tong)并(bing)封閉穿(chuan)(chuan)(chuan)孔筒(tong)(tong)的(de)下(xia)(xia)方;(4)將玻璃潤(run)滑劑(ji)施加到(dao)穿(chuan)(chuan)(chuan)孔筒(tong)(tong)中坯(pi)料的(de)上(shang)(shang)端面和(he)中心(xin)(xin)孔內;(5)冷卻鐓粗(cu)桿、鐓粗(cu)頭;(6)清(qing)(qing)理(li)、更換穿(chuan)(chuan)(chuan)(擴(kuo))孔頭;(7)從穿(chuan)(chuan)(chuan)(擴(kuo))孔筒(tong)(tong)中頂出空(kong)心(xin)(xin)坯(pi)和(he)剪(jian)切環;(8)冷卻、清(qing)(qing)理(li)、更換剪(jian)切環;(9)冷卻、清(qing)(qing)理(li)穿(chuan)(chuan)(chuan)(擴(kuo))孔筒(tong)(tong)內襯;(10)接受空(kong)心(xin)(xin)坯(pi)料,并(bing)將其(qi)傳送(song)到(dao)輸出輥道上(shang)(shang)。

以上列舉的機(ji)械和裝置(zhi)按照(zhao)自(zi)動化程(cheng)序依次工(gong)作,其(qi)結(jie)構(gou)和布置(zhi)取決(擴)孔(kong)(kong)坯料的質量和尺寸、穿孔(kong)(kong)機(ji)的結(jie)構(gou)形式、穿孔(kong)(kong)筒的工(gong)位設置(zhi)及(ji)其(qi)工(gong)位數量。

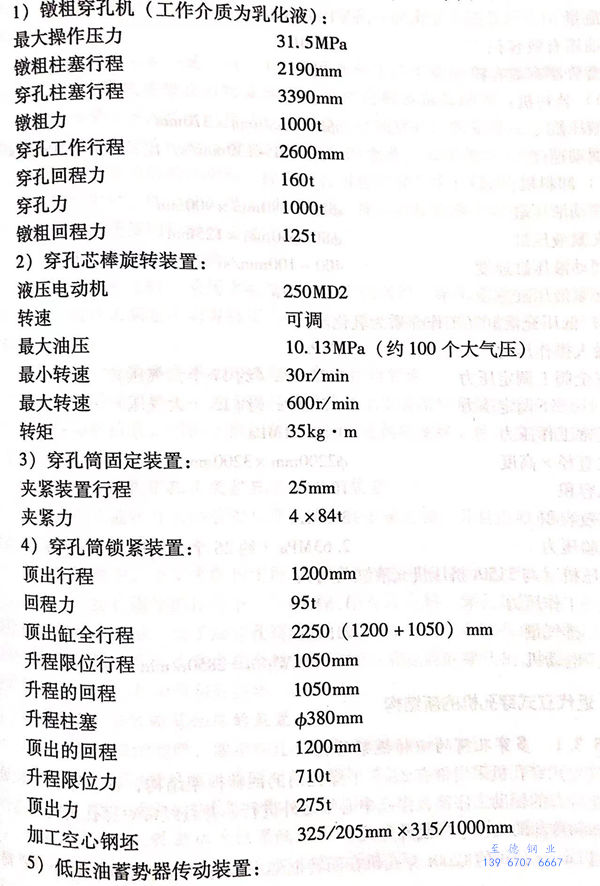

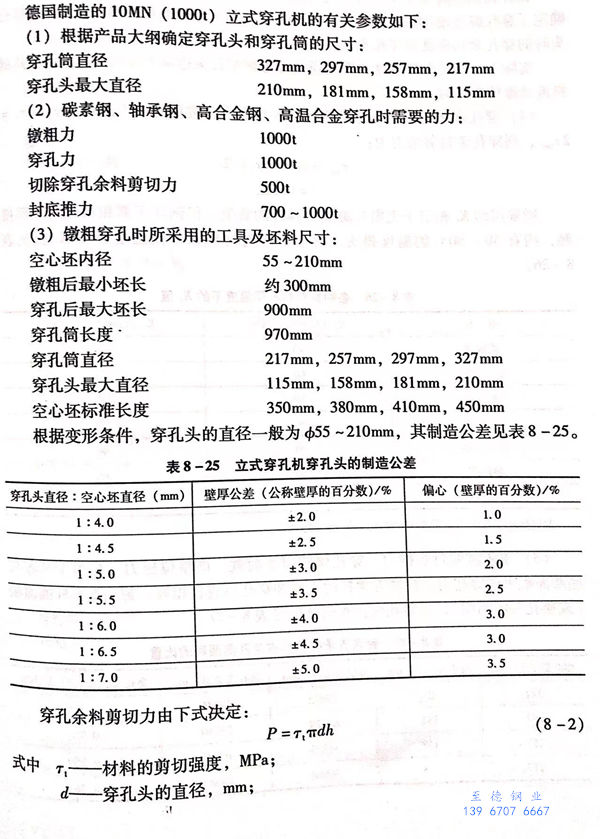

德國制造的10MN(1000t)立式穿(chuan)孔機的有關參數如下(xia):

穿孔余料應留的(de)(de)高度由可能得到(dao)的(de)(de)穿孔力的(de)(de)大小而定。

在穿(chuan)(chuan)孔(kong)(kong)(kong)余料高度等(deng)于穿(chuan)(chuan)孔(kong)(kong)(kong)頭直(zhi)徑的(de)(de)一(yi)半(ban)以(yi)前,穿(chuan)(chuan)孔(kong)(kong)(kong)過(guo)程為等(deng)穿(chuan)(chuan)孔(kong)(kong)(kong)力(li)進行。當確定(ding)了穿(chuan)(chuan)孔(kong)(kong)(kong)機在使用(yong)(yong)最大穿(chuan)(chuan)孔(kong)(kong)(kong)頭時(shi)的(de)(de)穿(chuan)(chuan)孔(kong)(kong)(kong)力(li)而不考(kao)慮其增長,則在使用(yong)(yong)最大穿(chuan)(chuan)孔(kong)(kong)(kong)頭時(shi)的(de)(de)穿(chuan)(chuan)孔(kong)(kong)(kong)余料高度為穿(chuan)(chuan)孔(kong)(kong)(kong)頭直(zhi)徑之半(ban)。

實際上,穿(chuan)孔余料高度的確(que)定尚須(xu)考慮(lv)到穿(chuan)孔頭邊角半徑(jing)的大小,以(yi)及其材料流動錐體的影響。

4. 穿(chuan)孔余(yu)料(liao)的剪切力與支承缸的封底推(tui)力

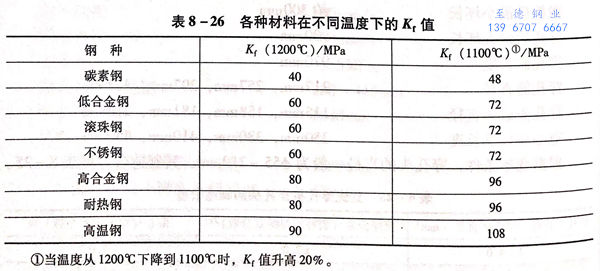

按照剪應力(li)理(li)論:σ1-σ3 = 2Tmax,則穿孔余料剪切力(li)為(wei): Tmax=(σ1-σ3)/2 τ=0.5Kf

所采用的Kf相當于無損失鐓壓過程時的數值,但鋼坯下部和穿孔筒底部接觸,約有50~80℃的溫度損失,對于不同的材料在不同溫度下的Kf值見表8-26。

5. 支承缸的封底推力(li)

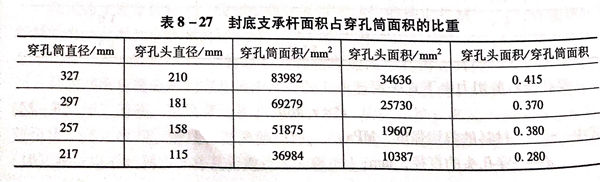

穿(chuan)孔(kong)(kong)(kong)筒(tong)的(de)(de)封(feng)底(di)荷載,即(ji)單位壓(ya)力,相當于分(fen)布在底(di)部面積上的(de)(de)穿(chuan)孔(kong)(kong)(kong)力,封(feng)底(di)支承桿(gan)的(de)(de)直徑(jing)(jing)和(he)穿(chuan)孔(kong)(kong)(kong)頭直徑(jing)(jing)相等(deng)。封(feng)底(di)支承桿(gan)的(de)(de)面積(或(huo)穿(chuan)孔(kong)(kong)(kong)頭的(de)(de)面積),占穿(chuan)孔(kong)(kong)(kong)筒(tong)面積的(de)(de)比值(zhi)見表8-27.

可見,當穿孔余(yu)料的高度不低(di)于(yu)穿孔頭(tou)直(zhi)徑之(zhi)半時,封底推力(li)能(neng)達到穿孔力(li)的50%就足夠了。為了充分利用(yong)穿孔力(li),并盡量減(jian)小(xiao)穿孔余(yu)料的厚度,則(ze)作(zuo)用(yong)于(yu)封底支(zhi)承桿(gan)上的穿孔力(li)的分量要(yao)增加,最大(da)可以增加到等于(yu)穿孔力(li)。

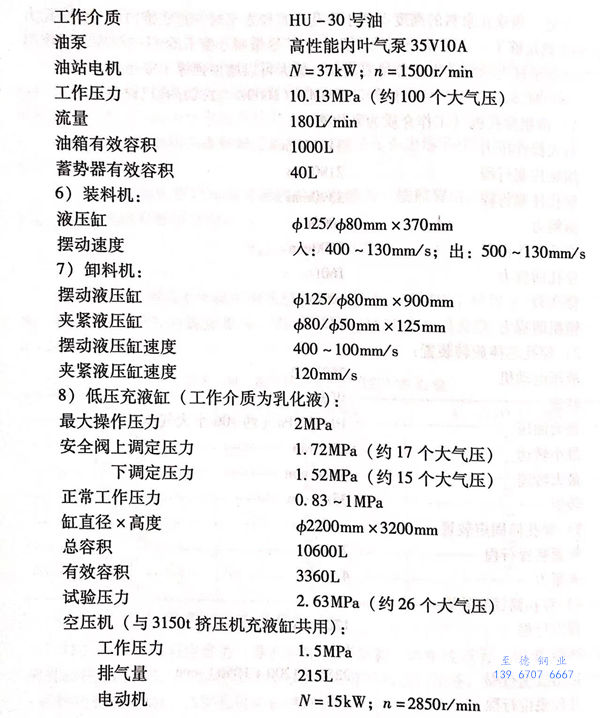

6. 31.5MN(3150t)擠壓車間(jian)10MN(1000t)立式穿孔機設備性能: