浙江至德鋼業有限公司采用立式穿孔機為臥式擠壓機提供空心坯料是不銹(xiu)鋼管(guan)擠壓不同于有色金屬擠壓的一個特點。立式穿孔機有利于穿孔工具與坯料金屬在穿孔中心線上的對中,提高了穿孔后空心坯的同心度,有利于擠壓鋼管壁厚均勻度的提高。而采用液壓傳動的穿孔機工作平穩,沒有沖擊,穿孔速度容易控制,并且結構也比較簡單。因此,近代的鋼管擠壓機組都是采用立式液壓穿孔機提供空心坯料。

與鋼(gang)擠壓(ya)(ya)機(ji)配套的(de)立(li)式(shi)穿孔機(ji)的(de)能(neng)力(li)(li)一般為所(suo)配套擠壓(ya)(ya)機(ji)能(neng)力(li)(li)的(de)35%~45%,并且隨著擠壓(ya)(ya)坯料合金化程度的(de)提(ti)高,立(li)式(shi)穿孔機(ji)的(de)能(neng)力(li)(li)與臥式(shi)擠壓(ya)(ya)機(ji)的(de)能(neng)力(li)(li)的(de)比(bi)例有(you)著提(ti)高的(de)趨勢。

如果立式穿孔(kong)機(ji)(ji)僅用于(yu)擴孔(kong)工(gong)藝,則(ze)其能力(li)與擠壓(ya)機(ji)(ji)能力(li)的比例可(ke)以減小到20%~35%,因為(wei)擴孔(kong)工(gong)藝時坯料無鐓粗工(gong)序(xu),而穿孔(kong)工(gong)藝中所(suo)需(xu)穿孔(kong)機(ji)(ji)的最大壓(ya)力(li)是鐓粗工(gong)序(xu)。

1. 多穿孔筒的回轉框架結構

近(jin)代立式穿(chuan)(chuan)孔(kong)機采用帶有2~3個(ge)(ge)穿(chuan)(chuan)孔(kong)筒(tong)的回轉框架(jia)結構,各個(ge)(ge)穿(chuan)(chuan)孔(kong)筒(tong)輪流工作(zuo),使所有的輔(fu)助(zhu)工序都在穿(chuan)(chuan)孔(kong)中(zhong)心(xin)線之外(wai)進行,并且經常(chang)對穿(chuan)(chuan)孔(kong)筒(tong)內襯進行機械(xie)清理和冷卻(que)的工作(zuo)也在線外(wai)完成。

英國Loewy 公司的1200t穿(chuan)孔機在回轉框架中裝有(you)2個(ge)穿(chuan)孔筒(tong)(tong),每個(ge)穿(chuan)孔筒(tong)(tong)布(bu)置4個(ge)工(gong)位,分別為:a. 卸去空心坯和(he)(he)剪切(qie)環(huan);b. 預鐓(dui)粗和(he)(he)穿(chuan)孔;c. 從穿(chuan)孔筒(tong)(tong)中推出空心坯;d.穿(chuan)孔筒(tong)(tong)內襯(chen)和(he)(he)剪切(qie)環(huan)清理、冷卻(que)。

這種結構(gou)允許方便地(di)布置(zhi)所(suo)有的輔助機械,縮短了穿(chuan)孔機的工作周(zhou)期。

日本神戶制鋼的23MN(2300t)穿(chuan)孔機帶(dai)有(you)3個(ge)(ge)穿(chuan)孔筒(tong)的回轉框架結構(gou),每個(ge)(ge)穿(chuan)孔筒(tong)布(bu)置了4個(ge)(ge)工位(wei),即裝料一(yi)鐓粗一(yi)穿(chuan)孔一(yi)取出(chu)空心(xin)坯及穿(chuan)孔筒(tong)內襯的清(qing)理和(he)冷卻。

穿孔(kong)筒(tong)的工(gong)(gong)位從4個減少到3個,穿孔(kong)機(ji)的工(gong)(gong)作周(zhou)期由30s增加到40秒(miao)。

2. 寬底座預(yu)應力張立(li)柱(zhu)固定螺帽(mao)的剛性框架結(jie)構

雙移(yi)動(dong)橫梁在(zai)(zai)導向(xiang)裝置上移(yi)動(dong);采用穿(chuan)孔針和穿(chuan)孔桿的(de)(de)套筒式連接(jie)系統(tong);采用流動(dong)水冷卻(que),以防止橫梁在(zai)(zai)熱膨脹(zhang)時產生的(de)(de)翹曲;采用預應力張立柱固(gu)定螺帽,提(ti)高(gao)(gao)封閉式框架(jia)結構的(de)(de)剛(gang)性,提(ti)高(gao)(gao)穿(chuan)孔過程中穿(chuan)孔中心線的(de)(de)同(tong)心度。

當(dang)坯(pi)料鐓粗時,兩(liang)個移動橫(heng)梁同步(bu)移動;穿(chuan)孔開始前兩(liang)個動梁分開并反向移動;移動橫(heng)梁的連接用機(ji)械方(fang)法來實現。

3. 多(duo)壓(ya)力缸結(jie)構

立式穿孔機(ji)的主(zhu)缸(gang)(gang),采用多缸(gang)(gang)結構,以(yi)(yi)實現鐓粗、穿孔或擴孔時,以(yi)(yi)各個壓力缸(gang)(gang)的組(zu)合選擇來滿足不同等(deng)級壓力的需求,并且將(jiang)主(zhu)缸(gang)(gang)布置在(zai)下面,以(yi)(yi)縮小穿孔機(ji)的總(zong)高(gao)度。

4. 液壓鎖緊穿孔筒(tong)及鐓粗(cu)穿孔桿的固(gu)定

采用專(zhuan)門的鎖緊機構,以實現自動而快(kuai)速(su)地安裝新(xin)穿孔(kong)筒和穿孔(kong)鐓粗桿(gan),并(bing)在(zai)空心坯的卸(xie)料位置,借助于推坯料機進行穿孔(kong)筒的更換(huan)。使更換(huan)穿孔(kong)筒的時間(jian)縮短到10~20min。

5. 安裝穿孔(kong)頭或擴孔(kong)頭的專門裝置

安裝穿孔頭或擴孔頭的(de)裝置(zhi)與(yu)穿孔筒回轉框架連(lian)鎖,并且由儲存器經冷卻和檢(jian)查(cha)后提(ti)供穿孔頭或擴孔頭。

在穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)過程中,下支承桿封閉剪切環的(de)孔(kong)(kong)(kong)(kong)(kong)(kong),在穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)余料達(da)到(dao)規定的(de)厚度時(shi),下支承桿在上穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)橫梁(liang)的(de)作用(yong)下,下降并切斷穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)余料。穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)針回(hui)程,穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)針頭和穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)余料留(liu)在下面。對于雙穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)(tong)的(de)穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)機(ji),穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)(tong)不在穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)中心線(xian)上時(shi),可(ke)用(yong)專(zhuan)門的(de)機(ji)械取(qu)(qu)出(chu)穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)頭和穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)余料,而對于三穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)筒(tong)(tong)的(de)穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)機(ji),則采用(yong)回(hui)轉的(de)卷筒(tong)(tong)將穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)頭、穿(chuan)(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)(kong)余料和剪切環一起(qi)取(qu)(qu)出(chu)。

6. 安裝(zhuang)新剪(jian)切環的裝(zhuang)置

通過不同工位的卷筒(tong),取(qu)走穿孔(kong)頭,穿孔(kong)余(yu)料和剪切環(huan)。

對于雙穿(chuan)孔(kong)筒(tong)的穿(chuan)孔(kong)機,采用專(zhuan)門的機械裝置將剪切(qie)環和坯料一起裝進穿(chuan)孔(kong)筒(tong)。

穿孔后(hou),用(yong)機(ji)械(xie)手從穿孔筒(tong)中取(qu)出的(de)剪切環在第(di)3個(ge)工位進行剪切環的(de)清(qing)理。

7. 將坯(pi)料由(you)水平位(wei)置(zhi)改變成垂直(zhi)位(wei)置(zhi)并裝進(jin)穿(chuan)孔筒中的機械裝置(zhi)

為了從穿孔(kong)(kong)筒中取出(chu)穿孔(kong)(kong)空心坯,安裝有專門的液(ye)壓(ya)推出(chu)裝置,其能力約為穿孔(kong)(kong)機主缸能力的1/3.

8. 穿孔筒的(de)清理(li)和冷卻(que)裝置

采用旋轉(zhuan)的金屬絲刷(shua)子,并(bing)在其(qi)中安(an)裝有固定的水噴(pen)霧器裝置。

9. 穿孔筒(tong)內襯的預熱器(qi)

穿(chuan)孔前(qian),穿(chuan)孔筒的(de)(de)預(yu)熱(re)(re)采用附(fu)加內熱(re)(re)式的(de)(de)感應(ying)(ying)加熱(re)(re)器,對于擠壓筒的(de)(de)過盈裝配和保持(chi)裝配后(hou)的(de)(de)預(yu)應(ying)(ying)力是必(bi)要的(de)(de)。

10. 穿孔針和敏(min)粗(cu)桿的套筒式(shi)連接機構

為了提高穿(chuan)(chuan)(chuan)孔空心(xin)(xin)坯的(de)壁厚精(jing)度(du),在現代穿(chuan)(chuan)(chuan)孔機上采用(yong)鐓(dui)粗(cu)桿(gan)和(he)穿(chuan)(chuan)(chuan)孔針運動的(de)套(tao)管系統。坯料鐓(dui)粗(cu)后,鐓(dui)粗(cu)桿(gan)并(bing)不返(fan)回,而是繼續保持和(he)其接觸。這樣可以讓穿(chuan)(chuan)(chuan)孔針精(jing)確地對準坯料中心(xin)(xin),并(bing)減小其自由長度(du)。以用(yong)穿(chuan)(chuan)(chuan)孔鐓(dui)粗(cu)桿(gan)頭和(he)專門的(de)穿(chuan)(chuan)(chuan)孔筒內襯套(tao)形成(cheng)補充的(de)穿(chuan)(chuan)(chuan)孔定心(xin)(xin)。

11. 穿孔(kong)機主輔設備的(de)自動化(hua)

A. 穿孔(kong)機的程序控制

穿(chuan)孔機的(de)(de)(de)電(dian)子控(kong)(kong)制(zhi)是自由可編程序的(de)(de)(de)控(kong)(kong)制(zhi),其還附帶一種操作(zuo)(zuo)控(kong)(kong)制(zhi)的(de)(de)(de)程序。這種電(dian)子控(kong)(kong)制(zhi)是新技術,可有以下(xia)幾種操作(zuo)(zuo)方(fang)法:a. 帶有連鎖的(de)(de)(de)更換工具的(de)(de)(de)操作(zuo)(zuo)開關(guan)以及調(diao)節穿(chuan)孔機空(kong)運轉(zhuan)的(de)(de)(de)操作(zuo)(zuo)開關(guan)均不用按鈕結構(gou);b. 穿(chuan)孔機的(de)(de)(de)主(zhu)(zhu)生(sheng)產(chan)開關(guan)及所有各種必(bi)要的(de)(de)(de)連鎖裝置(zhi)和所有各種輔助裝置(zhi)的(de)(de)(de)手(shou)動(dong)開關(guan);c. 部分(fen)自動(dong)化電(dian)路,其中(zhong)有單個的(de)(de)(de)自動(dong)匯集站,余下(xia)部分(fen)可用手(shou)動(dong)控(kong)(kong)制(zhi)進行(xing);d. 整個設備用自動(dong)化的(de)(de)(de)程序塊實現整個生(sheng)產(chan)過程的(de)(de)(de)自動(dong)化;e. 從控(kong)(kong)制(zhi)室(shi)的(de)(de)(de)主(zhu)(zhu)控(kong)(kong)制(zhi)臺上(shang)接通并監控(kong)(kong)設備的(de)(de)(de)所有各個部分(fen)。

B. 使(shi)用(yong)工業機(ji)器人(ren)

要阻止(zhi)工業(ye)機(ji)器人(ren)用于熱穿(擴)孔生產是(shi)困難的(de),特別是(shi)用于高溫(wen)(其(qi)(qi)溫(wen)度往往高達1200℃)和沉重(zhong)的(de)工件(jian)(其(qi)(qi)曲(qu)軸的(de)重(zhong)量高達250kg)以及在多塵埃的(de)環境(jing)中(zhong)的(de)繁重(zhong)作業(ye)。

要(yao)求在這(zhe)種不(bu)利的(de)生產條件下,機器人動作(zuo)的(de)準確(que)(que)(que)性(xing)也不(bu)能(neng)遭到破壞。特(te)別(bie)是(shi)當穿(擴)孔機裝料時,對尺(chi)寸和(he)位置的(de)準確(que)(que)(que)性(xing)和(he)穩定性(xing)均有很高的(de)要(yao)求,因為在很多(duo)情(qing)況下尺(chi)寸和(he)位置的(de)準確(que)(que)(que)性(xing)往往只(zhi)能(neng)偏差(cha)幾毫米。

機(ji)(ji)器(qi)(qi)人(ren)(ren)影(ying)響(xiang)經濟效益的(de)(de)重(zhong)大(da)因(yin)素是(shi)它的(de)(de)靈活性(xing)。這(zhe)(zhe)種(zhong)設備的(de)(de)“程(cheng)序(xu)(xu)”,即(ji)操作的(de)(de)有效距離,運動過程(cheng)和工(gong)(gong)作節(jie)奏必(bi)須能以簡(jian)單(dan)的(de)(de)方式加以調整(zheng)和變化,使(shi)這(zhe)(zhe)種(zhong)機(ji)(ji)器(qi)(qi)人(ren)(ren)除完成預先規(gui)定的(de)(de)任(ren)務外,還(huan)可令其做其他工(gong)(gong)作。這(zhe)(zhe)就要求機(ji)(ji)器(qi)(qi)人(ren)(ren)不僅具有干(gan)預機(ji)(ji)器(qi)(qi)人(ren)(ren)的(de)(de)機(ji)(ji)能的(de)(de)自(zi)由(you)可編程(cheng)序(xu)(xu),而且還(huan)要使(shi)任(ren)何一個沒有這(zhe)(zhe)種(zhong)高度發展(zhan)的(de)(de)專門知識的(de)(de)人(ren)(ren)都能使(shi)用這(zhe)(zhe)種(zhong)機(ji)(ji)器(qi)(qi)人(ren)(ren)。這(zhe)(zhe)種(zhong)所要求的(de)(de)自(zi)由(you)可編程(cheng)序(xu)(xu)即(ji)是(shi)“Teach-in-方法的(de)(de)自(zi)由(you)可編程(cheng)序(xu)(xu)”。

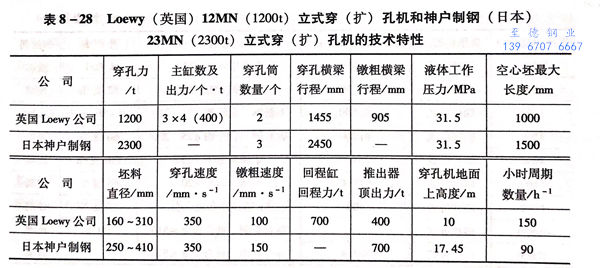

Loewy(英(ying)國)12MN(1200t)立式穿(擴)孔機和神戶制鋼(日本(ben))23MN(2300t)立式(shi)穿(chuan)(擴(kuo))孔機的技術特(te)性見表8-28.