當不銹鋼管坯料在感應器內加熱時,由于感應加熱的端部效應和坯料端部的散熱,導致加熱后的不銹鋼管坯料存在軸向溫差,進而使坯料在擠壓后引起鋼管的壁厚不均缺陷。為了確保擠壓不銹(xiu)鋼管的質量,必須使經感應加熱后的坯料的軸向溫差控制在±30℃左右。為此,坯料在感應加熱(再加熱)過程中需要進行端部功率補償:

1. 端部補償的原(yuan)理

感(gan)應(ying)器(qi)的(de)(de)電(dian)(dian)(dian)路由電(dian)(dian)(dian)感(gan)電(dian)(dian)(dian)容和(he)電(dian)(dian)(dian)阻組(zu)成,當將端(duan)(duan)(duan)部(bu)(bu)(bu)(bu)(bu)補償電(dian)(dian)(dian)容器(qi)并聯在感(gan)應(ying)器(qi)線路上時,使電(dian)(dian)(dian)路中(zhong)的(de)(de)阻抗值增高(gao),從(cong)而引(yin)起感(gan)應(ying)器(qi)的(de)(de)兩端(duan)(duan)(duan)與(yu)中(zhong)部(bu)(bu)(bu)(bu)(bu)的(de)(de)匝間電(dian)(dian)(dian)壓(ya)重(zhong)新分(fen)配,使主(zhu)感(gan)應(ying)器(qi)兩端(duan)(duan)(duan)電(dian)(dian)(dian)壓(ya)較低的(de)(de)部(bu)(bu)(bu)(bu)(bu)分(fen)得到(dao)(dao)了(le)(le)補償,并且導致感(gan)應(ying)器(qi)兩端(duan)(duan)(duan)部(bu)(bu)(bu)(bu)(bu)電(dian)(dian)(dian)壓(ya)增高(gao),使端(duan)(duan)(duan)部(bu)(bu)(bu)(bu)(bu)的(de)(de)磁(ci)通(tong)密度增加,即分(fen)配到(dao)(dao)鋼坯端(duan)(duan)(duan)部(bu)(bu)(bu)(bu)(bu)的(de)(de)功率增加,從(cong)而使加熱(re)(re)坯料的(de)(de)端(duan)(duan)(duan)部(bu)(bu)(bu)(bu)(bu)溫(wen)度得到(dao)(dao)了(le)(le)補償,降低了(le)(le)加熱(re)(re)(再加熱(re)(re))后坯料的(de)(de)軸向溫(wen)差。

2. 補(bu)償電(dian)容器容量的計算

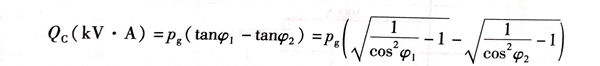

感應器的功率因數由cosφ1 補償到 cosφ2所需電容器的容量按下式計算:

3. 端部(bu)補(bu)償的(de)控制

傳(chuan)統的功率(lv)補(bu)(bu)償(chang)(chang)控制(zhi)方法(fa)是采用(yong)無功功率(lv)繼電(dian)(dian)器等組成的有觸點的系統來進行控制(zhi)。根(gen)據(ju)(ju)所測得(de)的電(dian)(dian)流、電(dian)(dian)壓、溫度等數值,將補(bu)(bu)償(chang)(chang)電(dian)(dian)容(rong)器的容(rong)量調節到(dao)最佳(jia)狀態(tai)。隨著計算機技術(shu)和電(dian)(dian)子技術(shu)的發(fa)展,近代一般(ban)都已采用(yong)無功功率(lv)自動(dong)補(bu)(bu)償(chang)(chang)裝置,根(gen)據(ju)(ju)所采集到(dao)的數據(ju)(ju),通過分析計算,自動(dong)切換補(bu)(bu)償(chang)(chang)電(dian)(dian)路,使之達到(dao)最佳(jia)效果(guo)。