用于不銹鋼焊接的焊絲分為實芯焊絲和藥芯焊絲兩(liang)大類,其生(sheng)產(chan)技術條件(jian)和制造工藝有較大的差別,使用(yong)(yong)特點也各(ge)不相同。不銹鋼實芯(xin)焊絲一般(ban)用(yong)(yong)于惰性(xing)氣體保護焊和埋(mai)弧(hu)焊,不銹鋼藥芯(xin)焊絲則用(yong)(yong)二氧化碳氣體保護焊、混合氣體保護焊和埋(mai)弧(hu)焊。

一、不銹鋼實芯(xin)焊(han)絲

不銹鋼實(shi)芯焊(han)(han)(han)絲(si)按(an)焊(han)(han)(han)接方法的不同(tong),可分為氣體(ti)保護焊(han)(han)(han)用(yong)焊(han)(han)(han)絲(si)和埋弧(hu)焊(han)(han)(han)用(yong)焊(han)(han)(han)絲(si)。

1. 氣(qi)體保(bao)護焊(han)用不銹鋼實芯焊(han)絲(si)的(de)型號和牌號

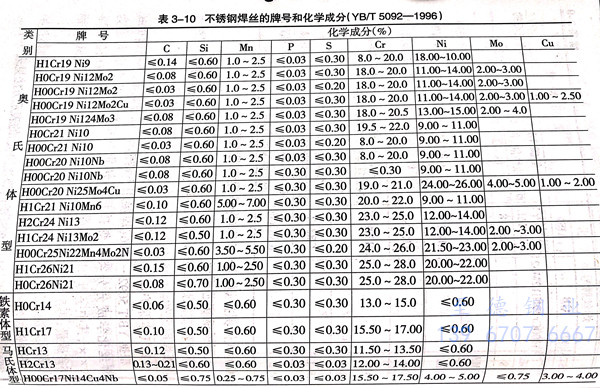

根據YB/T 5092-1996《焊(han)(han)(han)接用不銹(xiu)(xiu)鋼(gang)絲(si)》標準規定,不銹(xiu)(xiu)鋼(gang)焊(han)(han)(han)絲(si)按焊(han)(han)(han)絲(si)化學成分(fen)分(fen)類,焊(han)(han)(han)接用不銹(xiu)(xiu)鋼(gang)焊(han)(han)(han)絲(si)牌號的(de)表示(shi)方法(fa)為Hxxx,其中(zhong)字母“H”表示(shi)焊(han)(han)(han)接用焊(han)(han)(han)絲(si);H后面(mian)(mian)的(de)一位(wei)(wei)或兩位(wei)(wei)數(shu)字表示(shi)含(han)碳量(liang);再后面(mian)(mian)的(de)字母或數(shu)字表示(shi)其他合金(jin)元(yuan)素及(ji)其含(han)量(liang),與鋼(gang)材的(de)表示(shi)方法(fa)大致相同,如H00Cr21Ni10。

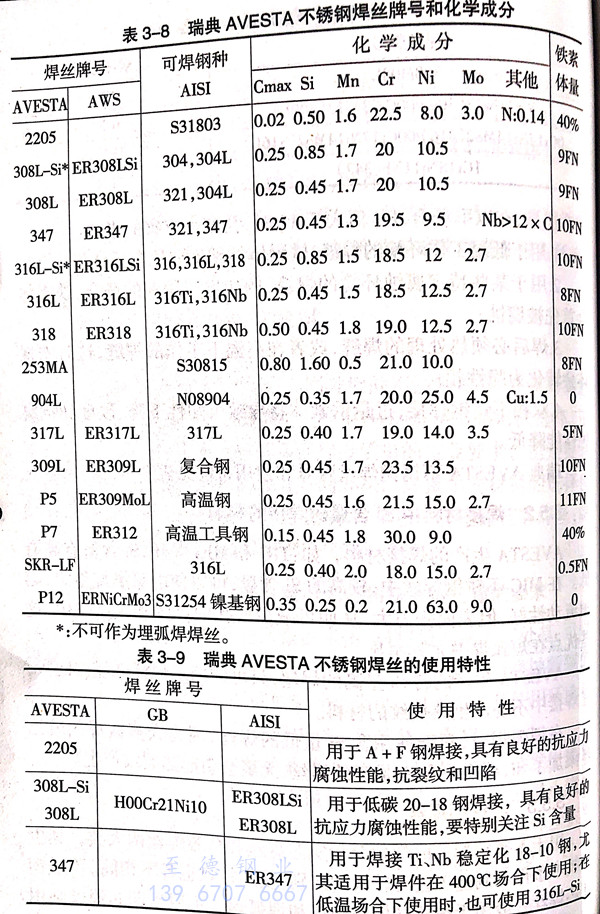

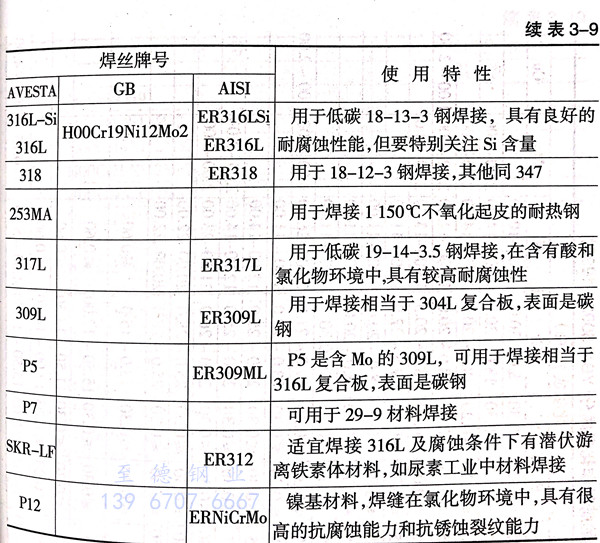

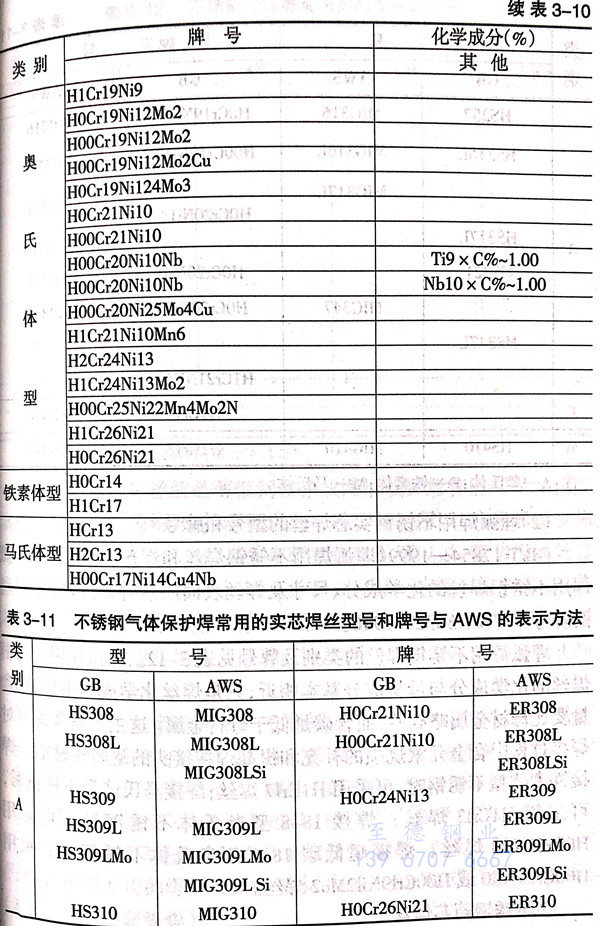

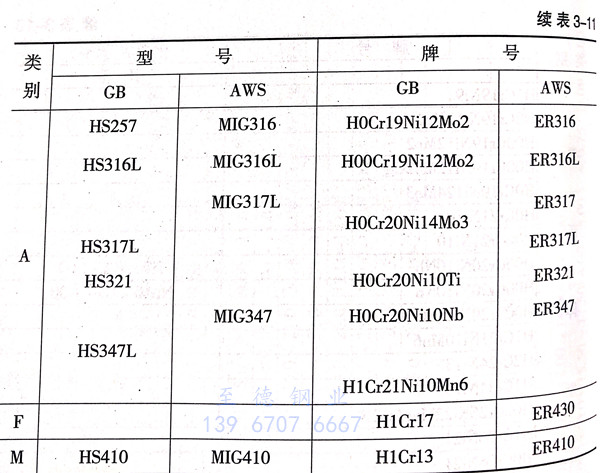

不銹鋼焊(han)絲的牌(pai)號(hao)和(he)(he)化學成分(fen)見表3-10,常用的不銹鋼氣體保護焊(han)實芯焊(han)絲型號(hao)和(he)(he)牌(pai)號(hao)與AWS(美國(guo)焊(han)接協會)的表示(shi)方法見表3-11。

2. 埋弧焊用不銹鋼實芯(xin)焊絲的型號(hao)和牌號(hao)

GB/T 17854-1999《埋弧焊(han)(han)用(yong)不(bu)銹鋼焊(han)(han)絲和(he)焊(han)(han)劑》中規定了埋弧焊(han)(han)用(yong)不(bu)銹鋼焊(han)(han)絲的化學(xue)成分、尺寸及焊(han)(han)絲表面(mian)質量等,并(bing)規定了焊(han)(han)絲的牌號按YB/T5092-1996。

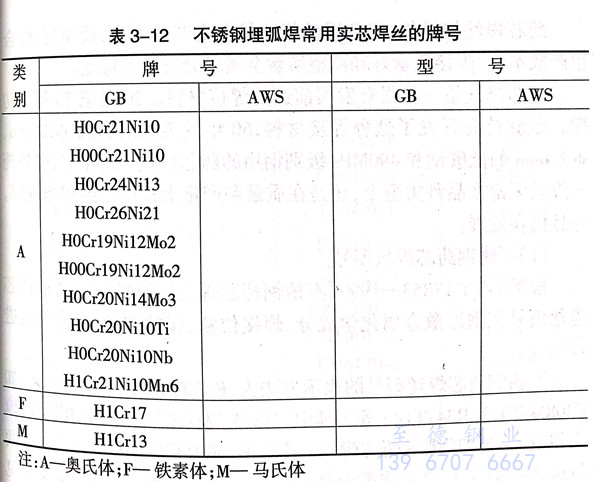

埋弧焊(han)用不(bu)銹鋼(gang)(gang)(gang)焊(han)絲的(de)類別(bie)及牌號見(jian)表3-12。埋弧焊(han)用不(bu)銹鋼(gang)(gang)(gang)焊(han)絲的(de)化學(xue)(xue)成分與母(mu)材成分基本(ben)相(xiang)近,只是焊(han)絲化學(xue)(xue)成分中(zhong)(zhong)鉻、鎳(nie)含量要比母(mu)材金屬略(lve)高些,而含碳量低于母(mu)材金屬。這主要是考慮(lv)到對焊(han)接(jie)(jie)(jie)過程(cheng)中(zhong)(zhong)合(he)金元素燒損的(de)補充(chong)和提高焊(han)接(jie)(jie)(jie)接(jie)(jie)(jie)頭的(de)耐腐(fu)蝕性能(neng)。焊(han)接(jie)(jie)(jie)鐵素體(ti)(ti)型(xing)不(bu)銹鋼(gang)(gang)(gang)時,可采(cai)用H1Cr17焊(han)絲;焊(han)接(jie)(jie)(jie)馬氏(shi)體(ti)(ti)型(xing)不(bu)銹鋼(gang)(gang)(gang)時,可采(cai)用H1Cr13焊(han)絲;焊(han)接(jie)(jie)(jie)18-8型(xing)奧氏(shi)體(ti)(ti)不(bu)銹鋼(gang)(gang)(gang)時,可采(cai)用H0Cr21Ni10焊(han)絲;焊(han)接(jie)(jie)(jie)超低碳18-8型(xing)奧氏(shi)體(ti)(ti)不(bu)銹鋼(gang)(gang)(gang)時,采(cai)用H00Cr21Ni10或H00Cr19Ni12Mo2焊(han)絲。

二、不銹鋼藥芯(xin)焊絲

不(bu)銹鋼(gang)藥芯(xin)焊(han)(han)(han)絲(si)(si)就是(shi)薄帶(dai)鋼(gang)在(zai)卷(juan)成(cheng)圓形或異形管的同時(shi),往里(li)填充一定成(cheng)分的藥粉(fen),經(jing)(jing)拉制而(er)成(cheng)的一種焊(han)(han)(han)絲(si)(si)。所以,藥芯(xin)焊(han)(han)(han)絲(si)(si)也(ye)稱管狀焊(han)(han)(han)絲(si)(si),是(shi)新發展起(qi)來的高效率焊(han)(han)(han)接(jie)材料(liao)。可以說,藥芯(xin)焊(han)(han)(han)絲(si)(si)既具有(you)藥皮焊(han)(han)(han)條(tiao)的配(pei)方可調性,同時(shi)又具有(you)二氧化碳焊(han)(han)(han)絲(si)(si)連續焊(han)(han)(han)接(jie)的優點。藥芯(xin)焊(han)(han)(han)絲(si)(si)與(yu)焊(han)(han)(han)條(tiao)及實芯(xin)焊(han)(han)(han)絲(si)(si)一樣,已(yi)經(jing)(jing)成(cheng)為(wei)焊(han)(han)(han)接(jie)加(jia)工的主要材料(liao),在(zai)焊(han)(han)(han)材中(zhong)所占(zhan)的比重逐年增(zeng)加(jia),國(guo)外已(yi)經(jing)(jing)達到(dao)30%~40%,我(wo)國(guo)僅達到(dao)0.2%~0.3%。

藥(yao)芯(xin)焊(han)(han)絲的(de)(de)種類按(an)其保(bao)護(hu)(hu)(hu)氣(qi)體(ti)來(lai)分(fen)(fen),可(ke)分(fen)(fen)為(wei)二氧化碳(tan)氣(qi)體(ti)保(bao)護(hu)(hu)(hu)、混合氣(qi)體(ti)保(bao)護(hu)(hu)(hu)和無(wu)保(bao)護(hu)(hu)(hu)(自保(bao)護(hu)(hu)(hu))三種。按(an)其有無(wu)造(zao)渣(zha)(zha)功能(neng)來(lai)分(fen)(fen),可(ke)分(fen)(fen)為(wei)“藥(yao)粉造(zao)渣(zha)(zha)型”和“金屬(shu)造(zao)渣(zha)(zha)型”兩種;按(an)造(zao)渣(zha)(zha)的(de)(de)性質(zhi)來(lai)分(fen)(fen),可(ke)分(fen)(fen)為(wei)“鈦(tai)型”(酸(suan)性)、“鈦(tai)鈣型”(中性或弱酸(suan)性)和“鈣型”(酸(suan)性)三種。此外,還(huan)有一些藥(yao)芯(xin)焊(han)(han)絲只是作為(wei)輸送合金成分(fen)(fen)的(de)(de)載(zai)體(ti),而無(wu)工(gong)藝性能(neng)方面(mian)的(de)(de)要求(qiu),配以專用的(de)(de)焊(han)(han)劑或保(bao)護(hu)(hu)(hu)氣(qi)體(ti)(大(da)多為(wei)Ar氣(qi))進行焊(han)(han)接或堆焊(han)(han)(埋弧焊(han)(han)或鎢極氬弧焊(han)(han))。

藥芯(xin)(xin)焊(han)絲與(yu)焊(han)條、實芯(xin)(xin)焊(han)絲相(xiang)比具有生產效率高,周(zhou)期(qi)(qi)短(duan),綜合生產成本低(di),焊(han)接(jie)質量(liang)好(hao)和調(diao)整熔敷金屬成分方便等特(te)點。藥芯(xin)(xin)焊(han)絲是(shi)一種很有發(fa)展(zhan)前(qian)途的焊(han)接(jie)材料。20世紀50年(nian)代初期(qi)(qi),歐洲首先開發(fa)了這種焊(han)接(jie)材料,60年(nian)代美(mei)國研制成Φ2.0mm、Φ2.4mm的低(di)碳鋼和490MPa級(ji)別鋼用(yong)的藥芯(xin)(xin)焊(han)絲。近年(nian)來,國外藥芯(xin)(xin)焊(han)絲無(wu)論在品種類(lei)型(xing)上,還(huan)是(shi)在質量(liang)和產量(liang)上都已達到相(xiang)當規模,并且仍在發(fa)展(zhan)。

1. 不銹鋼(gang)藥芯焊絲型號

根據(ju)(ju)GB/T 17853-1999《不銹鋼(gang)藥(yao)(yao)芯焊(han)絲》的規(gui)定(ding),不銹鋼(gang)藥(yao)(yao)芯焊(han)絲型號依據(ju)(ju)熔敷金屬化(hua)學成分、焊(han)接位置、保(bao)護類型、電流類型進行(xing)劃(hua)分。

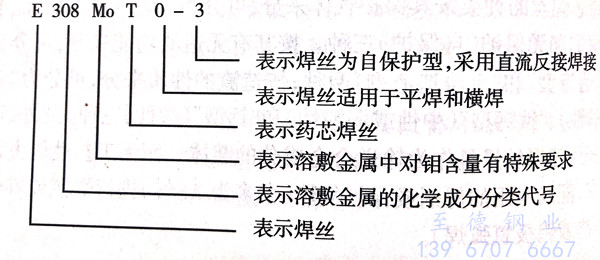

不銹(xiu)(xiu)鋼藥芯(xin)焊(han)(han)(han)絲(si)型(xing)號的(de)表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)方法為:E(或(huo)R)×××T×-×,如E308MoT0-3、R347T1-5等(deng)。其中字(zi)母(mu)“E”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)焊(han)(han)(han)絲(si);字(zi)母(mu)“R”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)填充焊(han)(han)(han)絲(si);字(zi)母(mu)“T”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)藥芯(xin)焊(han)(han)(han)絲(si);字(zi)母(mu)“E(或(huo)R)”后(hou)(hou)面(mian)的(de)xxx(前兩位(wei)或(huo)四位(wei)數(shu)字(zi))表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)熔敷金屬的(de)化學成分分類代號,具體(ti)內容見GB/T 17853-1999《不銹(xiu)(xiu)鋼藥芯(xin)焊(han)(han)(han)絲(si)》;如有特殊要(yao)求的(de)化學成分,將其元素(su)符(fu)(fu)號附加(jia)在數(shu)字(zi)后(hou)(hou)面(mian),或(huo)者用(yong)“L”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)碳含量較(jiao)低,用(yong)“H”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)碳含量較(jiao)高,用(yong)“K”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)焊(han)(han)(han)絲(si)應用(yong)于低溫環境;第四位(wei)x表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)適用(yong)的(de)焊(han)(han)(han)接(jie)(jie)位(wei)置(zhi),“0”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)用(yong)于平(ping)焊(han)(han)(han)和(he)橫焊(han)(han)(han),“1”表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)用(yong)于全位(wei)置(zhi)焊(han)(han)(han);半(ban)字(zi)符(fu)(fu)“-”后(hou)(hou)面(mian)的(de)x(第五位(wei)數(shu)字(zi))表(biao)(biao)(biao)(biao)(biao)示(shi)(shi)(shi)焊(han)(han)(han)接(jie)(jie)方法、保(bao)護(hu)氣體(ti)及焊(han)(han)(han)接(jie)(jie)電(dian)流類型(xing)。

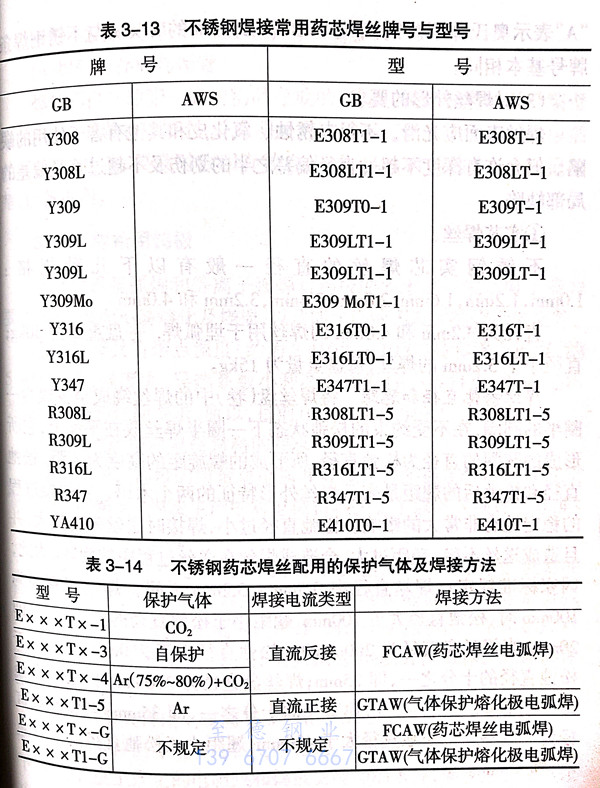

常用不銹鋼藥芯焊(han)絲(si)牌(pai)號(hao)(hao)與(yu)型(xing)(xing)號(hao)(hao)見表3-13,不銹鋼藥芯焊(han)絲(si)配(pei)用的保(bao)護(hu)氣體(ti)及焊(han)接方法見表3-14。不銹鋼藥芯焊(han)絲(si)型(xing)(xing)號(hao)(hao)舉例(li):

2. 不銹鋼藥芯焊(han)絲(si)牌號(hao)

目前(qian)國內企業使用(yong)的(de)不銹(xiu)鋼(gang)藥芯焊絲牌(pai)號較多(duo),多(duo)與(yu)企業名稱有關,并(bing)不統一。典型的(de)不銹(xiu)鋼(gang)藥芯焊絲牌(pai)表(biao)示(shi)(shi)方法(fa)為YB(或YA)××× -× 。其中字(zi)(zi)母(mu)“Y”表(biao)示(shi)(shi)藥芯焊絲,字(zi)(zi)母(mu)“B”表(biao)示(shi)(shi)不銹(xiu)鋼(gang),字(zi)(zi)母(mu)“A”表(biao)示(shi)(shi)奧氏體不銹(xiu)鋼(gang),字(zi)(zi)母(mu)“YB”(YA)后面的(de)×××與(yu)不銹(xiu)鋼(gang)焊條牌(pai)號基本相同。

三、對焊絲外形(xing)的要(yao)求

焊(han)絲表面應光滑,不(bu)得有(you)(you)(you)銹蝕、氧化皮和(he)其他有(you)(you)(you)害于使用的缺陷。但允許有(you)(you)(you)深度(du)不(bu)超過直(zhi)徑偏(pian)差之半的劃傷及不(bu)超過直(zhi)徑偏(pian)差的局部(bu)缺陷。

①. 實芯焊(han)絲

不銹鋼實芯焊絲的直徑一般有以下(xia)幾(ji)種規格:1.0mm,1.2mm,1.6mm,2.0mm,2.4mm,3.2mm和4.0mm。

直徑為3.2mm和4.0mm的焊(han)絲用(yong)于(yu)埋弧(hu)焊(han),每盤重量為30kg;直徑小于(yu)3.2mm的焊(han)絲,每盤重量為15kg。

焊(han)(han)(han)絲(si)(si)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)和翹距(ju)(ju)(ju) 將焊(han)(han)(han)絲(si)(si)盤(pan)(卷(juan))中(zhong)的(de)(de)(de)(de)焊(han)(han)(han)絲(si)(si)繞成(cheng)(cheng)至少成(cheng)(cheng)為(wei)一圈半的(de)(de)(de)(de)圓圈,在(zai)不(bu)受約(yue)束的(de)(de)(de)(de)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)狀態下一圈半焊(han)(han)(han)絲(si)(si)放在(zai)平面上,它(ta)所(suo)形(xing)(xing)成(cheng)(cheng)的(de)(de)(de)(de)圓圈的(de)(de)(de)(de)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)為(wei)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing),所(suo)形(xing)(xing)成(cheng)(cheng)的(de)(de)(de)(de)螺旋(xuan)距(ju)(ju)(ju)的(de)(de)(de)(de)高度為(wei)翹距(ju)(ju)(ju)。松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)和松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)后的(de)(de)(de)(de)翹距(ju)(ju)(ju)是表示焊(han)(han)(han)絲(si)(si)外(wai)形(xing)(xing)特征的(de)(de)(de)(de)兩個(ge)術(shu)語(yu),對焊(han)(han)(han)接過(guo)程(cheng)的(de)(de)(de)(de)穩定性有(you)非常大(da)的(de)(de)(de)(de)影響。松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)過(guo)小(xiao)(xiao),焊(han)(han)(han)接時(shi)送絲(si)(si)阻力(li)就大(da),并且造成(cheng)(cheng)送絲(si)(si)不(bu)穩。翹距(ju)(ju)(ju)過(guo)大(da),會造成(cheng)(cheng)焊(han)(han)(han)絲(si)(si)在(zai)送絲(si)(si)過(guo)程(cheng)中(zhong)的(de)(de)(de)(de)旋(xuan)轉。為(wei)此(ci),國家(jia)標準規定:焊(han)(han)(han)絲(si)(si)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)在(zai)0.5mm~3.2mm之(zhi)間,焊(han)(han)(han)絲(si)(si)盤(pan)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)為(wei)100mm時(shi),松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)大(da)于(yu)(yu)100mm,翹距(ju)(ju)(ju)小(xiao)(xiao)于(yu)(yu)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)的(de)(de)(de)(de)五分(fen)之(zhi)一,即20mm;當焊(han)(han)(han)絲(si)(si)盤(pan)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)為(wei)200mm時(shi),松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)大(da)于(yu)(yu)250mm,翹距(ju)(ju)(ju)小(xiao)(xiao)于(yu)(yu)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)的(de)(de)(de)(de)十分(fen)之(zhi)一,即25mm;焊(han)(han)(han)絲(si)(si)盤(pan)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)為(wei)300mm時(shi),松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)大(da)于(yu)(yu)350mm,翹距(ju)(ju)(ju)小(xiao)(xiao)于(yu)(yu)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)的(de)(de)(de)(de)十分(fen)之(zhi)一,即35mm;當焊(han)(han)(han)絲(si)(si)盤(pan)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)為(wei)350mm時(shi),松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)大(da)于(yu)(yu)400mm,翹距(ju)(ju)(ju)小(xiao)(xiao)于(yu)(yu)松(song)(song)(song)(song)(song)(song)弛(chi)(chi)(chi)(chi)直(zhi)(zhi)(zhi)(zhi)(zhi)(zhi)徑(jing)(jing)(jing)(jing)的(de)(de)(de)(de)十分(fen)之(zhi)一,即40mm。

②. 藥芯焊絲

不銹鋼藥芯焊絲(si)的直徑(jing)一(yi)般有以下幾種規格:1.0mm,1.2mm,1.6mm,2.0mm,2.4mm,3.2mm,和4.0mm。

直(zhi)徑為(wei)3.2mm和(he)4.0mm的焊絲用于(yu)埋弧(hu)焊,每(mei)盤(pan)(pan)重(zhong)量為(wei)30kg直(zhi)徑小于(yu)3.2mm的焊絲,每(mei)盤(pan)(pan)重(zhong)量為(wei)15kg。

四、焊絲(si)的(de)存放與保管

不(bu)(bu)銹鋼焊絲不(bu)(bu)得(de)與油(you)脂一(yi)類(lei)的物(wu)品存(cun)放(fang)的一(yi)起,應存(cun)放(fang)離(li)地(di)面及墻壁為300mm、干燥的貨架上,并有明顯準(zhun)確的標記。未用(yong)完的焊絲應捆扎(zha)好,不(bu)(bu)得(de)松弛,要及時(shi)收回(hui)存(cun)放(fang)在(zai)干燥、無油(you)污的地(di)方,并標記清楚(chu),以備再(zai)用(yong)。