不銹鋼工(gong)業管道(dao)的施(shi)工(gong)過(guo)程一般包(bao)(bao)括施(shi)工(gong)準備、現場安(an)(an)裝(zhuang)和(he)試(shi)車交(jiao)工(gong)。施(shi)工(gong)準備包(bao)(bao)括技(ji)術準 備、資源準備和(he)現場準備;現場安(an)(an)裝(zhuang)和(he)試(shi)車包(bao)(bao)括支吊(diao)架安(an)(an)裝(zhuang)、管道(dao)組成件現場裝(zhuang)配(pei)和(he)焊接、管道(dao)系統試(shi)驗、吹(chui)掃和(he)防腐保溫(wen)等。

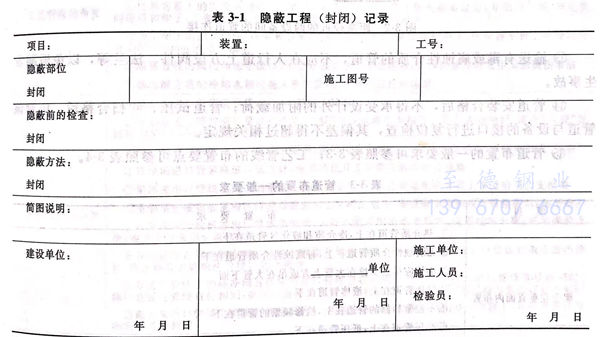

由于香蕉視頻app蘋果:不銹鋼壓力管道的用途和結構不同,具體施工程序也有所差別,化工企業管道大部分屬于工業管道,不銹鋼工業管道一般用來連接生產裝置中的各種設備以運輸工藝介質和壓縮空氣、氮氣、蒸汽等公用系統物料,為了便于操作和維修,除了少量在管溝內安裝外,一般都在地面支承結構上鋪設。其一般施工程序如圖3-1所示。埋地管道屬于隱蔽工程,由于在地下鋪設,所以不占地面空間,不影響人們的生產和生活活動,對氣候變化不敏感。但不易檢查和維修,易受地質變化影響而遭受損失,因此,埋地管道多用于管道結構比較簡單、 不需經常操作和維修的場合,在不銹鋼工業管道中則主要用于無毒、不可燃的公用系統管道的鋪設。

不銹鋼工(gong)業管(guan)(guan)(guan)(guan)(guan)道(dao)(dao)現場安裝是(shi)通(tong)過焊接、螺紋連接或法蘭連接等方法將(jiang)預(yu)制管(guan)(guan)(guan)(guan)(guan)段、成(cheng)(cheng)品閥門、管(guan)(guan)(guan)(guan)(guan) 件、緊(jin)固件、密(mi)封件、支撐(cheng)件和(he)管(guan)(guan)(guan)(guan)(guan)道(dao)(dao)附屬設備(bei)按照設計要求(qiu)與其他工(gong)藝(yi)設備(bei)進行組裝,形(xing)成(cheng)(cheng)完整的管(guan)(guan)(guan)(guan)(guan)道(dao)(dao)體系的施工(gong)過程。根(gen)據(ju)文明施工(gong)、先(xian)(xian)(xian)易后(hou)難的原則,壓力管(guan)(guan)(guan)(guan)(guan)道(dao)(dao)現場敷設應采(cai)用(yong)下(xia)列(lie)順序:先(xian)(xian)(xian)地下(xia),后(hou)地上,先(xian)(xian)(xian)大管(guan)(guan)(guan)(guan)(guan),后(hou)小(xiao)管(guan)(guan)(guan)(guan)(guan);先(xian)(xian)(xian)夾套(tao)管(guan)(guan)(guan)(guan)(guan),后(hou)單(dan)體管(guan)(guan)(guan)(guan)(guan);先(xian)(xian)(xian)高壓管(guan)(guan)(guan)(guan)(guan),后(hou) 中、低壓管(guan)(guan)(guan)(guan)(guan)。