當不銹鋼管浮銹較厚,首先用錘子等敲擊手動工具除掉鋼管表面上的厚銹,使銹層脫落。然后使用鋼絲刷、鋼砂布或鏟刀等手工工具刮或磨,除掉表面上所有銹蝕層,待露出金屬本色后再用棉紗拉、刷干凈。

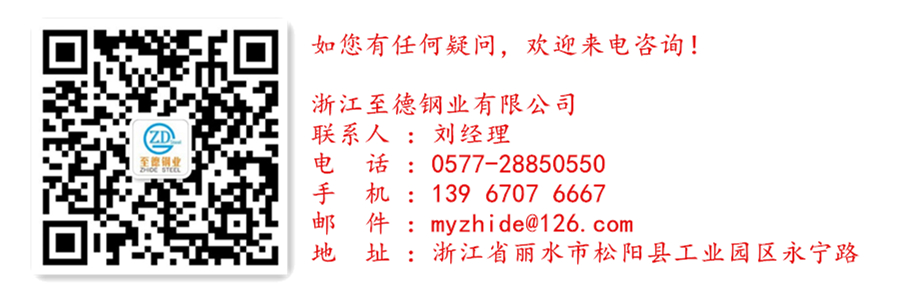

動(dong)力(li)工具(ju)為由動(dong)力(li)驅(qu)(qu)動(dong)的(de)(de)(de)旋轉方式或沖擊式除銹工具(ju),如(ru)可(ke)以使用圓盤狀的(de)(de)(de)鋼(gang)絲(si)刷。鋼(gang)絲(si)刷通過軟軸有電動(dong)機驅(qu)(qu)動(dong)。如(ru)圖 2-1所示(shi),鋼(gang)絲(si)刷的(de)(de)(de)直徑根據(ju)不同的(de)(de)(de)清洗(xi)管(guan)(guan)徑而更(geng)換,清洗(xi)管(guan)(guan)段(duan)可(ke)長達12米(mi)。

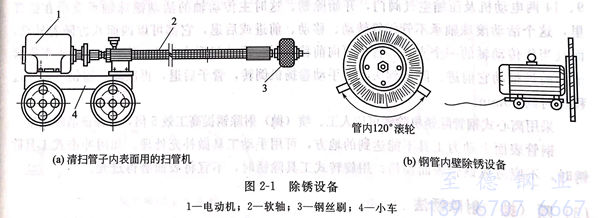

圖 2-2 所示為離心(xin)式(shi)鋼管除(chu)銹機,可同時清除(chu)不銹鋼管內(nei)外壁的(de)氧化皮(pi)或(huo)疏松的(de)銹。該機是利用離心(xin)力的(de)原理制(zhi)成的(de)。主(zhu)要機件(jian)有鋼管小車、砂輪機架、傳動(dong)機構及手(shou)動(dong)卷楊機等。

除銹不銹鋼(gang)管用(yong)吊車(che)安(an)放在(zai)(zai)鋼(gang)管小車(che)上,在(zai)(zai)小車(che)的(de)(de)尾部(bu)用(yong)鋼(gang)絲繩直接通過輕便(bian)鐵(tie)軌上的(de)(de)導向滑輪(lun)(lun)與手動(dong)卷(juan)楊機相連。小車(che)上安(an)裝1.7KW電動(dong)機,經減(jian)速(su)器用(yong)鏈條帶動(dong)托輥使管子轉動(dong),轉速(su)為15~20r/mm。在(zai)(zai)臥(wo)裝砂(sha)輪(lun)(lun)機圓盤鋼(gang)絲刷的(de)(de)摩擦(ca)作(zuo)用(yong)下,去除鋼(gang)管外壁的(de)(de)銹蝕。臥(wo)裝砂(sha)輪(lun)(lun)和(he)圓盤鋼(gang)絲刷裝在(zai)(zai)砂(sha)輪(lun)(lun)機架上。

當(dang)電動(dong)(dong)(dong)機轉動(dong)(dong)(dong)時,通(tong)過十字(zi)接頭帶動(dong)(dong)(dong)主傳(chuan)(chuan)動(dong)(dong)(dong)軸,主傳(chuan)(chuan)動(dong)(dong)(dong)軸通(tong)過 2~3 副滾珠軸承(cheng),支(zhi)撐(cheng)在(zai)套管(guan)里,套管(guan)支(zhi)撐(cheng)在(zai)裝有托輥的(de)(de)活(huo)動(dong)(dong)(dong)小(xiao)車上,主傳(chuan)(chuan)動(dong)(dong)(dong)軸的(de)(de)端部兩塊鋼(gang)絲(si)刷緊密的(de)(de)接觸管(guan)壁,摩擦管(guan)壁鐵(tie)銹(xiu),同時壓縮空氣管(guan)將除下的(de)(de)氧化鐵(tie)銹(xiu)隨時吹出管(guan)外。整個管(guan)子的(de)(de)移動(dong)(dong)(dong),進或(huo)退,是以(yi) 800~1000 mm/min的(de)(de)速度(du)推動(dong)(dong)(dong)鋼(gang)管(guan)小(xiao)車在(zai)輪軌上行駛來實(shi)現的(de)(de)。

操作時(shi)(shi),兩手搖(yao)卷揚機,使鋼(gang)(gang)管(guan)小車(che)移到管(guan)端,進(jin)入主傳動(dong)(dong)(dong)(dong)軸(zhou)鋼(gang)(gang)絲刷的(de)同時(shi)(shi)開(kai)動(dong)(dong)(dong)(dong)兩電機及壓縮空氣閥門,開(kai)始除銹。這時(shi)(shi)主傳動(dong)(dong)(dong)(dong)軸(zhou)的(de)活(huo)(huo)動(dong)(dong)(dong)(dong)滾珠軸(zhou)承支(zhi)撐在(zai)不銹鋼(gang)(gang)管(guan)里(li),這個(ge)活(huo)(huo)動(dong)(dong)(dong)(dong)滾珠軸(zhou)承不管(guan)鋼(gang)(gang)管(guan)轉(zhuan)動(dong)(dong)(dong)(dong)、移動(dong)(dong)(dong)(dong)、前(qian)(qian)進(jin)或后退,它(ta)都(dou)可(ke)以四面八(ba)方隨著轉(zhuan)動(dong)(dong)(dong)(dong),而且當作傳動(dong)(dong)(dong)(dong)軸(zhou)的(de)一個(ge)支(zhi)點。管(guan)子(zi)再向前(qian)(qian)移動(dong)(dong)(dong)(dong)時(shi)(shi),活(huo)(huo)動(dong)(dong)(dong)(dong)門形支(zhi)架倒下,活(huo)(huo)動(dong)(dong)(dong)(dong)小車(che)靠管(guan)子(zi)的(de)前(qian)(qian)進(jin)推動(dong)(dong)(dong)(dong)它(ta)的(de)前(qian)(qian)進(jin)。除銹到頭時(shi)(shi),手動(dong)(dong)(dong)(dong)卷揚機倒轉(zhuan),管(guan)子(zi)后退,再次除一遍銹。這一過(guo)程(cheng)歷(li)時(shi)(shi)約15分鐘。

采用離(li)心式鋼管除銹(xiu)機可(ke)比人(ren)工、噴(拋)射除銹(xiu)提高工效5倍,并保證(zheng)清除質量(liang)。不銹鋼管表面(mian)上動(dong)力工具不(bu)(bu)能達(da)到的地方,可以用手動(dong)工具做補(bu)充處(chu)理。如果用沖擊式工具除銹(xiu)時,不(bu)(bu)應(ying)造成鋼管的損傷;用旋轉(zhuan)式工具除銹(xiu)時,不(bu)(bu)宜(yi)將表面磨得(de)過光。