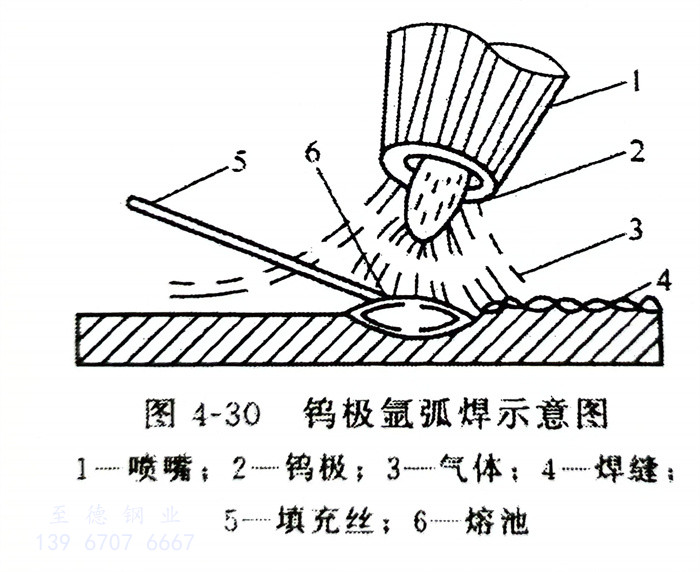

鎢(wu)(wu)(wu)(wu)極(ji)惰(duo)性氣(qi)(qi)(qi)(qi)體保(bao)護(hu)(hu)電(dian)(dian)弧(hu)(hu)(hu)焊(han)(han)(han)(tungsten inert gas welding,TIG),從屬(shu)于(yu)GTAW中的(de)非熔化極(ji)惰(duo)性氣(qi)(qi)(qi)(qi)體保(bao)護(hu)(hu)焊(han)(han)(han),焊(han)(han)(han)接(jie)時(shi)(shi)鎢(wu)(wu)(wu)(wu)極(ji)只起導(dao)電(dian)(dian)作(zuo)用,不作(zuo)填(tian)充金屬(shu)(不熔化),如(ru)圖4-30所示。根據保(bao)護(hu)(hu)氣(qi)(qi)(qi)(qi)體的(de)不同,分為(wei)鎢(wu)(wu)(wu)(wu)極(ji)氬弧(hu)(hu)(hu)焊(han)(han)(han)和鎢(wu)(wu)(wu)(wu)極(ji)氦弧(hu)(hu)(hu)焊(han)(han)(han)。焊(han)(han)(han)接(jie)時(shi)(shi),惰(duo)性氣(qi)(qi)(qi)(qi)體氬氣(qi)(qi)(qi)(qi)或(huo)(huo)氦氣(qi)(qi)(qi)(qi)(Ar或(huo)(huo)He)通(tong)過(guo)焊(han)(han)(han)槍(qiang)或(huo)(huo)其他裝置加入焊(han)(han)(han)接(jie)區(qu)(或(huo)(huo)待焊(han)(han)(han)區(qu)),鎢(wu)(wu)(wu)(wu)極(ji)與被(bei)焊(han)(han)(han)工件之間通(tong)電(dian)(dian)產(chan)(chan)生電(dian)(dian)弧(hu)(hu)(hu),電(dian)(dian)弧(hu)(hu)(hu)在(zai)惰(duo)性氣(qi)(qi)(qi)(qi)體的(de)氣(qi)(qi)(qi)(qi)氛中燃(ran)燒。氬氣(qi)(qi)(qi)(qi)或(huo)(huo)氦氣(qi)(qi)(qi)(qi)(Ar或(huo)(huo)He)在(zai)焊(han)(han)(han)接(jie)過(guo)程中與鎢(wu)(wu)(wu)(wu)極(ji)、焊(han)(han)(han)件、填(tian)充焊(han)(han)(han)絲不發生任何化學、冶金作(zuo)用、惰(duo)性氣(qi)(qi)(qi)(qi)體保(bao)護(hu)(hu)焊(han)(han)(han)的(de)顯著(zhu)特點是電(dian)(dian)弧(hu)(hu)(hu)燃(ran)燒穩定,能(neng)(neng)有效地隔絕周圍空氣(qi)(qi)(qi)(qi),使(shi)(shi)熔池(chi)、填(tian)充絲不被(bei)氧化和氮化,因(yin)而(er)能(neng)(neng)獲(huo)得(de)高質量焊(han)(han)(han)縫(feng),且能(neng)(neng)進行全位置焊(han)(han)(han)接(jie)。但鎢(wu)(wu)(wu)(wu)極(ji)所通(tong)過(guo)的(de)電(dian)(dian)流(liu)密(mi)度(du)受到限制,若通(tong)過(guo)電(dian)(dian)流(liu)密(mi)度(du)太大,鎢(wu)(wu)(wu)(wu)極(ji)會燒損,使(shi)(shi)焊(han)(han)(han)縫(feng)金屬(shu)產(chan)(chan)生夾鎢(wu)(wu)(wu)(wu)缺欠(qian)。由(you)于(yu)鎢(wu)(wu)(wu)(wu)極(ji)氬弧(hu)(hu)(hu)焊(han)(han)(han)電(dian)(dian)弧(hu)(hu)(hu)能(neng)(neng)量密(mi)度(du)低,也不能(neng)(neng)獲(huo)得(de)較(jiao)大的(de)熔深和較(jiao)高的(de)生產(chan)(chan)率。采用鎢(wu)(wu)(wu)(wu)極(ji)氦弧(hu)(hu)(hu)焊(han)(han)(han)時(shi)(shi),使(shi)(shi)用與鎢(wu)(wu)(wu)(wu)極(ji)氬弧(hu)(hu)(hu)焊(han)(han)(han)同樣的(de)電(dian)(dian)流(liu)密(mi)度(du),鎢極氦弧焊的電弧電壓較高,電弧熱功率高。氦氣作為熱能的載體,它的熱傳導能比氬氣約大9倍。這樣,就有大量的熱能輸送到焊接熔池中去,從而獲得較大的熔深和得到較高的生產率。但是氦氣來源較為困難,價格比氬氣高20~30倍、同時氦氣的密度比氬氣小,要達到同樣的保護效果,氦氣的消耗量高出很多,所以氨弧焊成本很高。焊接薄的和中等厚度的奧氏體型不銹鋼板一般極少采用,只有在焊接關鍵焊件時才使用氦弧焊。

鎢極(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han)時(shi),母材金屬加熱特點(主(zhu)要(yao)指能(neng)量密(mi)度和熱功率大小(xiao))介于氣焊(han)(han)(han)和焊(han)(han)(han)條電(dian)弧(hu)焊(han)(han)(han)之間,在很小(xiao)的(de)(de)(de)焊(han)(han)(han)接電(dian)流(≤10A)下(xia),電(dian)弧(hu)仍可穩(wen)定燃燒,特別適于焊(han)(han)(han)接薄(bo)件(jian)或超薄(bo)件(jian)奧氏體型(xing)不銹鋼的(de)(de)(de)焊(han)(han)(han)接構件(jian)。鎢極(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han)時(shi)能(neng)清(qing)晰地觀察到焊(han)(han)(han)接熔池(chi)和熔透(tou)情況(kuang)、因此,在要(yao)求(qiu)保證(zheng)焊(han)(han)(han)透(tou)及(ji)要(yao)求(qiu)背面成(cheng)形的(de)(de)(de)情況(kuang)下(xia),單面焊(han)(han)(han)采用內(nei)壁(或背面)通氬(ya)(ya)氣的(de)(de)(de)鎢極(ji)氬(ya)(ya)弧(hu)打底焊(han)(han)(han)的(de)(de)(de)方(fang)法,在國內(nei)外(wai)已(yi)得到普遍(bian)應用。鎢極(ji)氬(ya)(ya)弧(hu)焊(han)(han)(han)采用的(de)(de)(de)填充絲為裸焊(han)(han)(han)絲,在施焊(han)(han)(han)過程(cheng)中,不會產生飛濺、焊(han)(han)(han)縫(feng)成(cheng)形美觀,焊(han)(han)(han)縫(feng)上(shang)不存在渣殼(ke),焊(han)(han)(han)后不需清(qing)理。

鎢極氬弧焊電弧的熱功率低,焊接速度相對其他電弧焊而言比較小,由于奧氏體不(bu)銹鋼管導熱能力較差,如鎢極氬弧焊的焊接速度很慢時、會導致焊接接頭冷卻速度緩慢,在400~800℃的危險溫度區間停留時間較長,會影響焊接接頭耐腐蝕能力(包括晶間腐蝕和均勻腐蝕)。