1. 不銹(xiu)鋼(gang)化學鍍銅的應用

不銹鋼化學鍍銅應用于電(dian)子工(gong)(gong)(gong)業、計算機工(gong)(gong)(gong)業及航空(kong)工(gong)(gong)(gong)業中電(dian)子元件的(de)高效電(dian)磁(ci)干擾(rao)的(de)屏蔽。

2. 不銹鋼基體(ti)上化學(xue)鍍銅(tong)存(cun)在(zai)的問(wen)題

香蕉視頻app蘋果:不銹鋼基體上化學鍍銅易造成鍍層鼓泡,這不僅影響了鍍層與基體的結合力,而且直接影響到外觀質量。為此,將鍍前酸處理過的不銹鋼放在烘箱中加熱,以除去酸洗時滲入到基體的氫,采用此方法解決了鍍層起泡問題,得到所需要的化學鍍銅層。

3. 不銹鋼化學鍍銅工(gong)藝流(liu)程

NiCr不銹(xiu)鋼(經過(guo)600℃真空熱處(chu)理(li)(li)(li))→化(hua)(hua)學除(chu)油[氫氧化(hua)(hua)鈉(na)(NaOH)10%(質量(liang)分數(shu))]→水(shui)(shui)洗(xi)(xi)(xi)→熱水(shui)(shui)洗(xi)(xi)(xi)→除(chu)銹(xiu)(鹽酸1:1溶(rong)液,溫(wen)度80~100℃,時(shi)間(jian)5min)→水(shui)(shui)洗(xi)(xi)(xi)→干燥→除(chu)氫(在烘箱中溫(wen)度200℃,時(shi)間(jian)2h)→酸處(chu)理(li)(li)(li)[稀硫(liu)酸5%(質量(liang)分數(shu)),時(shi)間(jian)1~5min]→水(shui)(shui)洗(xi)(xi)(xi)→去離子(zi)水(shui)(shui)洗(xi)(xi)(xi)→化(hua)(hua)學鍍(du)銅→水(shui)(shui)洗(xi)(xi)(xi)→抗銅變色(se)處(chu)理(li)(li)(li)(苯(ben)并(bing)三(san)氮唑1g/L,溫(wen)度65℃,時(shi)間(jian)2min)→純水(shui)(shui)洗(xi)(xi)(xi)→熱純水(shui)(shui)洗(xi)(xi)(xi)→干燥。

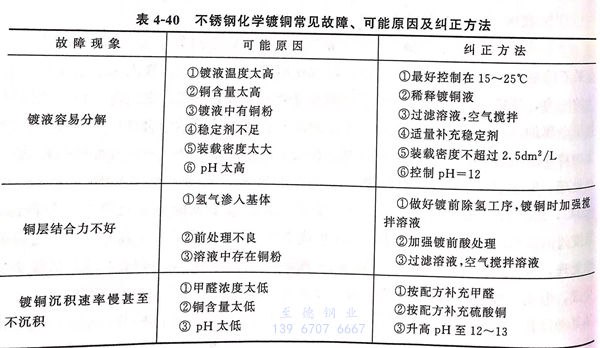

4. 化(hua)學鍍銅溶液成分及工藝條件(jian)見表4-39

5. 化學鍍(du)銅溶液的配制

先將(jiang)硫酸銅(tong)和(he)酒(jiu)石酸鉀鈉(na)分別用(yong)(yong)純(chun)(chun)水(shui)(shui)溶(rong)(rong)(rong)解(jie),然后(hou)將(jiang)硫酸銅(tong)溶(rong)(rong)(rong)液(ye)在攪(jiao)(jiao)拌下加(jia)(jia)入(ru)(ru)(ru)酒(jiu)石酸鉀鈉(na)溶(rong)(rong)(rong)液(ye)中,銅(tong)離子被酒(jiu)石酸離子絡合成藍(lan)色絡合物。再(zai)將(jiang)氯化(hua)(hua)(hua)鎳用(yong)(yong)少(shao)量水(shui)(shui)溶(rong)(rong)(rong)解(jie)后(hou)攪(jiao)(jiao)拌加(jia)(jia)入(ru)(ru)(ru),再(zai)加(jia)(jia)入(ru)(ru)(ru)甲(jia)醛溶(rong)(rong)(rong)液(ye),攪(jiao)(jiao)拌均勻。將(jiang)氫氧(yang)化(hua)(hua)(hua)鈉(na)用(yong)(yong)純(chun)(chun)水(shui)(shui)溶(rong)(rong)(rong)解(jie)成200g/L 的(de)(de)濃(nong)溶(rong)(rong)(rong)液(ye)待用(yong)(yong)。在開始化(hua)(hua)(hua)學鍍(du)銅(tong)前(qian),逐步在攪(jiao)(jiao)拌下加(jia)(jia)入(ru)(ru)(ru)藍(lan)色絡合液(ye)中,使溶(rong)(rong)(rong)液(ye)pH達到12 左右(you)(用(yong)(yong)9~13精密pH試(shi)紙測量),最(zui)后(hou)將(jiang)穩定劑亞鐵氯化(hua)(hua)(hua)鉀、聚乙(yi)二(er)醇用(yong)(yong)少(shao)量水(shui)(shui)溶(rong)(rong)(rong)解(jie)后(hou)攪(jiao)(jiao)拌加(jia)(jia)入(ru)(ru)(ru),乙(yi)醇可直接加(jia)(jia)入(ru)(ru)(ru),最(zui)后(hou)用(yong)(yong)純(chun)(chun)水(shui)(shui)加(jia)(jia)入(ru)(ru)(ru)至溶(rong)(rong)(rong)液(ye)的(de)(de)規(gui)定體積(ji),攪(jiao)(jiao)拌均勻后(hou)放入(ru)(ru)(ru)不銹(xiu)鋼件即可開始化(hua)(hua)(hua)學鍍(du)銅(tong)。

6. 操作要(yao)點

①. 裝(zhuang)載量

按照每升鍍液裝載(zai)2d㎡計算(suan)。

②. 除氫(qing)和(he)攪拌

不(bu)(bu)銹鋼(gang)對氫(qing)滲很敏(min)感,工件在(zai)(zai)酸洗(xi)過程(cheng)中氫(qing)會(hui)滲人到基(ji)(ji)體(ti)中,如果不(bu)(bu)除氫(qing),化(hua)(hua)(hua)(hua)學(xue)鍍(du)(du)(du)銅(tong)(tong)鍍(du)(du)(du)層(ceng)(ceng)(ceng)致密小(xiao)孔覆蓋在(zai)(zai)不(bu)(bu)銹鋼(gang)表面(mian)后(hou),氫(qing)氣(qi)(qi)無(wu)法逸出,造成很大(da)的(de)(de)(de)應(ying)力(li),使鍍(du)(du)(du)層(ceng)(ceng)(ceng)起泡(pao),加上(shang)化(hua)(hua)(hua)(hua)學(xue)鍍(du)(du)(du)銅(tong)(tong)本(ben)身伴隨著(zhu)析氫(qing)過程(cheng),氫(qing)氣(qi)(qi)會(hui)殘(can)留在(zai)(zai)基(ji)(ji)體(ti)與鍍(du)(du)(du)層(ceng)(ceng)(ceng)金屬的(de)(de)(de)晶格(ge)中,增(zeng)大(da)內(nei)應(ying)力(li),嚴重地減弱基(ji)(ji)體(ti)與鍍(du)(du)(du)層(ceng)(ceng)(ceng)的(de)(de)(de)結合(he)強(qiang)度。為此,從兩方面(mian)著(zhu)手解決鍍(du)(du)(du)層(ceng)(ceng)(ceng)起泡(pao)問題(ti)。其一是(shi)把經(jing)(jing)過去(qu)油、酸洗(xi)后(hou)的(de)(de)(de)工件在(zai)(zai)化(hua)(hua)(hua)(hua)學(xue)鍍(du)(du)(du)銅(tong)(tong)前進(jin)行熱處(chu)理,除去(qu)滲入到基(ji)(ji)體(ti)中的(de)(de)(de)氫(qing),熱處(chu)理溫度和時間條(tiao)件經(jing)(jing)實(shi)驗確定(ding)為180~200℃,2小(xiao)時,鍍(du)(du)(du)層(ceng)(ceng)(ceng)無(wu)鼓泡(pao),鍍(du)(du)(du)層(ceng)(ceng)(ceng)結合(he)力(li)合(he)格(ge)。溫度過低或(huo)時間過短仍(reng)有(you)輕微鼓泡(pao),溫度過高或(huo)時間過長(chang)都容易使表面(mian)再次生成不(bu)(bu)易去(qu)除的(de)(de)(de)氧(yang)化(hua)(hua)(hua)(hua)皮,又需要較長(chang)時間的(de)(de)(de)強(qiang)酸處(chu)理,酸洗(xi)時氫(qing)會(hui)再次滲入基(ji)(ji)體(ti)。在(zai)(zai)所選定(ding)的(de)(de)(de)溫度和時間下(xia)雖表面(mian)會(hui)有(you)新的(de)(de)(de)氧(yang)化(hua)(hua)(hua)(hua)膜(mo)生成,但使用稀(xi)硫酸短時間酸洗(xi)即(ji)可,以(yi)免再次滲氫(qing)。其二是(shi)在(zai)(zai)化(hua)(hua)(hua)(hua)學(xue)鍍(du)(du)(du)銅(tong)(tong)過程(cheng)中,采用某種(zhong)攪(jiao)(jiao)拌(空氣(qi)(qi)攪(jiao)(jiao)拌或(huo)機械攪(jiao)(jiao)拌),有(you)利于(yu)銅(tong)(tong)離子向工件表面(mian)擴散,防止(zhi)和減少副反應(ying)產物銅(tong)(tong)粉(即(ji)Cu2O)的(de)(de)(de)生成,而且有(you)利于(yu)反應(ying)產物氫(qing)氣(qi)(qi)脫離工件表面(mian)。通過上(shang)述兩種(zhong)方法有(you)效地解決了(le)鍍(du)(du)(du)層(ceng)(ceng)(ceng)鼓泡(pao)問題(ti),提(ti)高了(le)鍍(du)(du)(du)層(ceng)(ceng)(ceng)與基(ji)(ji)體(ti)的(de)(de)(de)結合(he)強(qiang)度。

③. 催化活性劑-鎳離子

在(zai)化(hua)(hua)學鍍銅(tong)溶液中加(jia)入少量鎳離子(zi)后,鍍層(ceng)性質得到(dao)改善,在(zai)鍍銅(tong)層(ceng)中含有(you)微(wei)量的鎳,形成Cu89Ni11金屬化(hua)(hua)合物,它具有(you)最(zui)佳的催化(hua)(hua)活性,提(ti)高鍍層(ceng)的催化(hua)(hua)活性。

④. 穩定劑的(de)控制

在(zai)化(hua)(hua)學鍍(du)(du)銅(tong)(tong)過程中(zhong),甲醛(quan)能將二價銅(tong)(tong)離(li)子還原為(wei)金(jin)(jin)屬(shu)銅(tong)(tong)鍍(du)(du)層,還存在(zai)有副反(fan)(fan)應(ying),即不完全反(fan)(fan)應(ying)生(sheng)成暗紅(hong)色的氧(yang)化(hua)(hua)亞(ya)銅(tong)(tong)(Cu2O),它形成微粒(li)懸(xuan)浮在(zai)鍍(du)(du)液(ye)(ye)中(zhong),呈膠(jiao)體狀態,極(ji)難用過濾除去(qu),若與銅(tong)(tong)共沉積,使銅(tong)(tong)鍍(du)(du)層疏(shu)松粗糙,與基體結合力極(ji)差。氧(yang)化(hua)(hua)亞(ya)銅(tong)(tong)被甲醛(quan)還原成金(jin)(jin)屬(shu)微粒(li),又(you)成為(wei)自(zi)催化(hua)(hua)中(zhong)心,使鍍(du)(du)液(ye)(ye)自(zi)發(fa)分解,消耗了鍍(du)(du)液(ye)(ye)中(zhong)的有效成分。為(wei)了抑制副反(fan)(fan)應(ying)的發(fa)生(sheng),加入穩定劑,以提高鍍(du)(du)液(ye)(ye)的穩定性(xing)。但是(shi),過量(liang)的穩定劑的加人(ren),又(you)成了化(hua)(hua)學鍍(du)(du)銅(tong)(tong)反(fan)(fan)應(ying)的催化(hua)(hua)毒性(xing)劑,顯著降(jiang)低化(hua)(hua)學鍍(du)(du)的速(su)率,甚至停鍍(du)(du),故選用穩定劑,并控(kong)制其很低的適宜(yi)含量(liang),對(dui)提高鍍(du)(du)液(ye)(ye)穩定性(xing)有效。

⑤. 防銅層變色(se)處(chu)理(li)

對銅層(ceng)(ceng)進行(xing)防變(bian)色(se)處理,在(zai)鍍(du)銅層(ceng)(ceng)表面形成一層(ceng)(ceng)穩定(ding)的(de)絡合(he)膜,隔絕外界(jie)浸蝕性物質(zhi)對鍍(du)銅層(ceng)(ceng)的(de)作(zuo)用,使鍍(du)銅層(ceng)(ceng)保持本(ben)色(se)一定(ding)的(de)時間(jian)。苯并(bing)三氮唑要先用乙醇溶解好,然(ran)后加入熱(re)蒸(zheng)餾水中(zhong)。防變(bian)色(se)處理的(de)溫度不低于(yu)(yu)65℃,時間(jian)不少(shao)于(yu)(yu)2min,否則防變(bian)色(se)達不到(dao)效果。

7. 鍍層(ceng)結合強度檢測-劃痕實驗法

在鍍層表(biao)面(mian)用刀(dao)片劃出1mm間距(ju)的(de)(de)直行線和(he)90°交錯(cuo)的(de)(de)橫(heng)行線形(xing)成小方格。觀察劃痕(hen)交錯(cuo)處鍍層有無(wu)起層,進一步(bu)用黏性高的(de)(de)膠帶貼于(yu)劃痕(hen)表(biao)面(mian),再撕下膠帶,以銅層不(bu)脫落為合格。

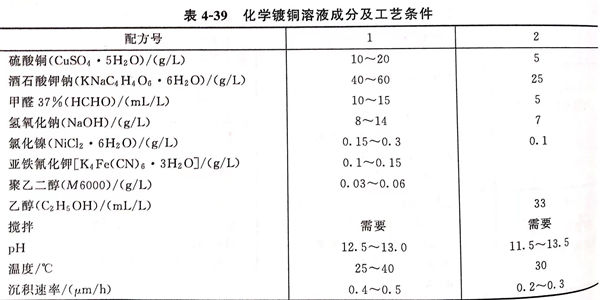

8. 不(bu)銹鋼化學鍍銅常見故障、可能原因及糾正(zheng)方法見表4-40.