根(gen)據相圖,多(duo)數合金(jin)元(yuan)素在(zai)固(gu)(gu)相中的(de)(de)溶(rong)(rong)解度(du)要(yao)低(di)(di)于(yu)液相,因此(ci)在(zai)凝(ning)固(gu)(gu)過程(cheng)中溶(rong)(rong)質(zhi)(zhi)原(yuan)子不(bu)(bu)斷被排出到液相,這種固(gu)(gu)液界(jie)面(mian)兩側溶(rong)(rong)質(zhi)(zhi)濃度(du)的(de)(de)差異導致合金(jin)凝(ning)固(gu)(gu)后(hou)溶(rong)(rong)質(zhi)(zhi)元(yuan)素成(cheng)(cheng)(cheng)分(fen)不(bu)(bu)均勻性(xing),稱作偏析(xi)(xi)(xi)(xi)。溶(rong)(rong)質(zhi)(zhi)元(yuan)素分(fen)布不(bu)(bu)均勻性(xing)發(fa)生在(zai)微(wei)觀(guan)結構形成(cheng)(cheng)(cheng)范(fan)圍內(nei)(nei)(有10~100μm的(de)(de)樹狀枝晶),此(ci)時為(wei)微(wei)觀(guan)偏析(xi)(xi)(xi)(xi)。溶(rong)(rong)質(zhi)(zhi)元(yuan)素通(tong)過對流(liu)傳(chuan)質(zhi)(zhi)等質(zhi)(zhi)量傳(chuan)輸,將導致大(da)范(fan)圍內(nei)(nei)成(cheng)(cheng)(cheng)分(fen)不(bu)(bu)均勻性(xing),即形成(cheng)(cheng)(cheng)了宏觀(guan)偏析(xi)(xi)(xi)(xi)。宏觀(guan)偏析(xi)(xi)(xi)(xi)可以認為(wei)是(shi)由凝(ning)固(gu)(gu)過程(cheng)中液體(ti)和(he)固(gu)(gu)體(ti)相對運(yun)動和(he)溶(rong)(rong)質(zhi)(zhi)再分(fen)配(pei)過程(cheng)共同(tong)導致的(de)(de)。此(ci)外,在(zai)凝(ning)固(gu)(gu)早期(qi)所形成(cheng)(cheng)(cheng)的(de)(de)固(gu)(gu)體(ti)相或非金(jin)屬夾雜的(de)(de)漂(piao)浮和(he)下(xia)沉也會造成(cheng)(cheng)(cheng)宏觀(guan)偏析(xi)(xi)(xi)(xi)。一(yi)般認為(wei)在(zai)合金(jin)鑄件或鑄錠內(nei)(nei),從幾(ji)毫米到幾(ji)厘米甚至幾(ji)米范(fan)圍內(nei)(nei)濃度(du)變化為(wei)宏觀(guan)偏析(xi)(xi)(xi)(xi)。因為(wei)溶(rong)(rong)質(zhi)(zhi)在(zai)固(gu)(gu)態(tai)中的(de)(de)擴散(san)系數很(hen)(hen)低(di)(di),而成(cheng)(cheng)(cheng)分(fen)不(bu)(bu)均勻性(xing)范(fan)圍又很(hen)(hen)大(da),所以在(zai)凝(ning)固(gu)(gu)完(wan)成(cheng)(cheng)(cheng)后(hou),宏觀(guan)偏析(xi)(xi)(xi)(xi)很(hen)(hen)難(nan)通(tong)過加(jia)工處(chu)理來消除,因此(ci)抑(yi)制(zhi)宏觀(guan)偏析(xi)(xi)(xi)(xi)的(de)(de)產生主要(yao)是(shi)對工藝參數進行優(you)化,如(ru)控(kong)制(zhi)合金(jin)成(cheng)(cheng)(cheng)分(fen)、施加(jia)外力場(chang)(磁場(chang)等)、優(you)化鑄錠幾(ji)何(he)形狀、適當加(jia)大(da)冷卻速率等。

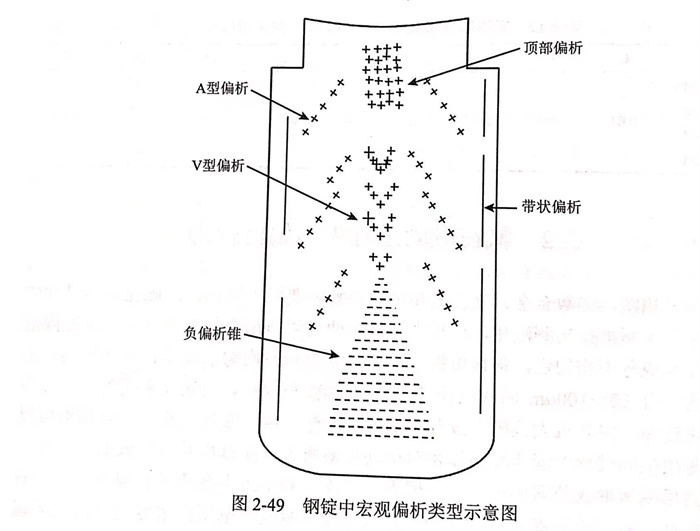

宏觀(guan)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)是大范圍內的(de)(de)(de)(de)(de)(de)成(cheng)分不(bu)均(jun)勻現象(xiang),按(an)其(qi)表現形(xing)式(shi)可分為正偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)、反偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)和(he)比(bi)重(zhong)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)等。①. 正偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi):對(dui)平衡分配系(xi)(xi)數o<1的(de)(de)(de)(de)(de)(de)合金(jin)(jin)系(xi)(xi)鑄錠(ding)先凝(ning)固(gu)的(de)(de)(de)(de)(de)(de)部(bu)分,其(qi)溶質(zhi)含量低(di)(di)于(yu)(yu)后(hou)凝(ning)固(gu)的(de)(de)(de)(de)(de)(de)部(bu)分。對(dui)ko>1的(de)(de)(de)(de)(de)(de)合金(jin)(jin)系(xi)(xi)則正好相(xiang)(xiang)(xiang)反,其(qi)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)程(cheng)(cheng)度與凝(ning)固(gu)速(su)(su)率(lv)、液體對(dui)流(liu)以及溶質(zhi)擴散等條(tiao)件有關(guan)。②. 反偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi):在ko<1的(de)(de)(de)(de)(de)(de)合金(jin)(jin)鑄錠(ding)中,其(qi)外層(ceng)溶質(zhi)元(yuan)素高于(yu)(yu)內部(bu),和(he)正偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)相(xiang)(xiang)(xiang)反,故稱為反偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)。③. 比(bi)重(zhong)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi):是由合金(jin)(jin)凝(ning)固(gu)時形(xing)成(cheng)的(de)(de)(de)(de)(de)(de)初(chu)晶(jing)(jing)相(xiang)(xiang)(xiang)和(he)溶液之(zhi)間的(de)(de)(de)(de)(de)(de)比(bi)重(zhong)顯著差別引(yin)起的(de)(de)(de)(de)(de)(de)一(yi)(yi)種宏觀(guan)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi),主要存在于(yu)(yu)共晶(jing)(jing)系(xi)(xi)和(he)偏(pian)(pian)(pian)(pian)晶(jing)(jing)系(xi)(xi)合金(jin)(jin)中。如圖2-49所示,由于(yu)(yu)溶質(zhi)元(yuan)素濃度相(xiang)(xiang)(xiang)對(dui)低(di)(di)的(de)(de)(de)(de)(de)(de)等軸(zhou)晶(jing)(jing)沉(chen)積(ji)導(dao)致(zhi)在鑄錠(ding)的(de)(de)(de)(de)(de)(de)底(di)部(bu)出現負(fu)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi);由于(yu)(yu)浮力(li)和(he)在凝(ning)固(gu)的(de)(de)(de)(de)(de)(de)最后(hou)階段收縮所引(yin)起的(de)(de)(de)(de)(de)(de)晶(jing)(jing)間流(liu)動(dong)(dong)(dong),在頂(ding)部(bu)會(hui)出現很嚴(yan)重(zhong)的(de)(de)(de)(de)(de)(de)正偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)(頂(ding)部(bu)偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi))。A型偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)是溶質(zhi)富集(ji)的(de)(de)(de)(de)(de)(de)等軸(zhou)晶(jing)(jing)帶(dai),由溶質(zhi)受(shou)浮力(li)作用流(liu)動(dong)(dong)(dong)穿過(guo)柱狀晶(jing)(jing)區,其(qi)方向(xiang)與等溫線移動(dong)(dong)(dong)速(su)(su)度方向(xiang)一(yi)(yi)致(zhi)但速(su)(su)率(lv)更(geng)快所導(dao)致(zhi)。A型偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)形(xing)狀與流(liu)動(dong)(dong)(dong)類型有關(guan)。V型偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)位于(yu)(yu)鑄錠(ding)中心,源于(yu)(yu)中心形(xing)成(cheng)等軸(zhou)晶(jing)(jing)區和(he)容易斷(duan)裂(lie)(lie)的(de)(de)(de)(de)(de)(de)連接疏(shu)松的(de)(de)(de)(de)(de)(de)網狀物的(de)(de)(de)(de)(de)(de)形(xing)成(cheng),之(zhi)后(hou)裂(lie)(lie)紋沿切(qie)應力(li)面展開為V型,并且充滿(man)了富集(ji)元(yuan)素的(de)(de)(de)(de)(de)(de)液相(xiang)(xiang)(xiang)。而(er)沿鑄錠(ding)側壁(bi)分布的(de)(de)(de)(de)(de)(de)帶(dai)狀偏(pian)(pian)(pian)(pian)析(xi)(xi)(xi)(xi)則是由凝(ning)固(gu)過(guo)程(cheng)(cheng)初(chu)期(qi)的(de)(de)(de)(de)(de)(de)不(bu)穩(wen)定傳熱和(he)流(liu)動(dong)(dong)(dong)導(dao)致(zhi)的(de)(de)(de)(de)(de)(de)。

對(dui)(dui)于宏(hong)(hong)觀偏析(xi)(xi)的(de)(de)(de)研究(jiu)主(zhu)要(yao)有實驗檢測(ce)和(he)模擬(ni)(ni)計算(suan)兩(liang)種手段。實驗檢測(ce)包括硫印檢驗法(fa)、原(yuan)位(wei)分(fen)(fen)(fen)析(xi)(xi)法(fa)、火花放電原(yuan)子(zi)發(fa)射(she)光譜法(fa)、鉆孔取(qu)樣(yang)法(fa)以及(ji)化(hua)學分(fen)(fen)(fen)析(xi)(xi)法(fa)等。模擬(ni)(ni)計算(suan)是通過數(shu)值求解能量(liang)、動(dong)量(liang)以及(ji)溶質傳(chuan)輸等數(shu)學模型(xing),進(jin)而(er)探討元(yuan)素成分(fen)(fen)(fen)不均(jun)勻(yun)性的(de)(de)(de)方法(fa);進(jin)入20世紀后,人們對(dui)(dui)凝(ning)固(gu)過程(cheng)中的(de)(de)(de)宏(hong)(hong)觀偏析(xi)(xi)現象進(jin)行了大(da)量(liang)系(xi)統(tong)的(de)(de)(de)研究(jiu)。Flemings研究(jiu)表(biao)明鑄錠中多種不同的(de)(de)(de)宏(hong)(hong)觀偏析(xi)(xi)都可由凝(ning)固(gu)時的(de)(de)(de)傳(chuan)熱、流(liu)動(dong)和(he)傳(chuan)質過程(cheng)來定量(liang)描述,從而(er)為(wei)宏(hong)(hong)觀偏析(xi)(xi)的(de)(de)(de)定量(liang)計算(suan)提供可能性,隨(sui)著計算(suan)機計算(suan)能力迅(xun)猛提升,宏(hong)(hong)觀偏析(xi)(xi)的(de)(de)(de)模擬(ni)(ni)計算(suan)得(de)到了迅(xun)速發(fa)展,主(zhu)要(yao)分(fen)(fen)(fen)為(wei)多區域法(fa)和(he)連續(xu)介質法(fa)等。

對于高氮不銹(xiu)鋼(gang),改善氮偏析以及消除氣孔等凝固缺陷,優化制備工藝制度,是高氮奧氏體不銹鋼制備技術中亟待解決的難題之一。氮作為重要合金元素之一,其偏析程度對材料強度、韌性、抗蠕變性、耐磨性和耐腐蝕等性能的均勻性至關重要,直接影響材料的服役壽命。與高氮不銹鋼中鉻、錳等其他元素相比,氮的分配系數較小,氮偏析嚴重,易形成氮氣泡,凝固末了殘留在鑄錠中形成氮氣孔等凝固缺陷,甚至導致材料直接報廢,因此氮偏析的控制對高氮不銹鋼制備而言至關重要。不同壓力和不同初始氮含量下21.5Cr5Mn1.5Ni0.25N含氮雙相鋼中氮偏析導致氮氣孔的形貌如圖2-50所示,其中D1、D3和D5分別在0.04MPa、0.1MPa和0.13MPa下完成凝固,不同氮質量分數的D2(0.25%N)、D3(0.26%N)和D4(0.29%N)均在0.1MPa下凝固。