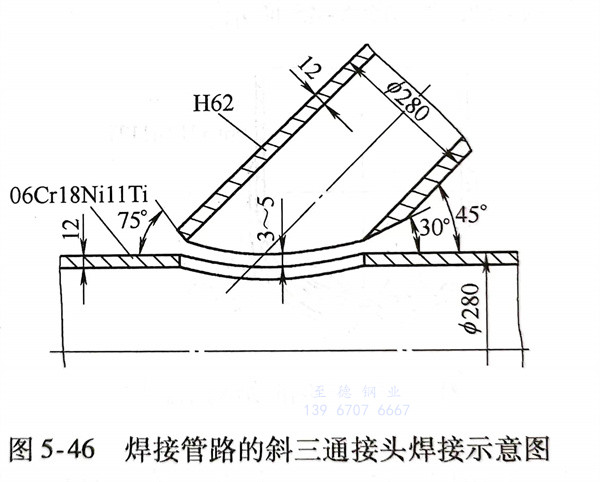

浙江至德鋼業有限公司制氧工程的外部管路是由大量黃銅(H62)和(06Cr18Ni11Ti)不銹鋼管組成的管路,需要在現場施工焊接。其管內徑為140~280mm,壁厚為8~12mm,工作壓力為3.75MPa,圖5-46為焊接管路斜三通接頭的焊接示意圖。

1. 焊(han)接性

黃銅(H62)熔(rong)(rong)點比不(bu)銹鋼(06Cr18Ni11Ti)低(di)400℃還(huan)多(duo),而熱(re)導率為06Cr18Nil1Ti的(de)6.5倍之多(duo)。焊(han)(han)接(jie)(jie)過程中易形成(cheng)低(di)熔(rong)(rong)點共(gong)晶體,隨之在(zai)焊(han)(han)接(jie)(jie)熔(rong)(rong)池中冷卻凝固,殘留(liu)在(zai)焊(han)(han)縫(feng)中,為形成(cheng)熱(re)裂(lie)紋(wen)創(chuang)造(zao)了條件。加之其線脹系(xi)數與原有(you)兩種(zhong)金屬(shu)中的(de)線脹系(xi)數有(you)很(hen)大差異(yi),形成(cheng)組織應(ying)(ying)力(li),并在(zai)焊(han)(han)接(jie)(jie)過程焊(han)(han)接(jie)(jie)接(jie)(jie)頭(tou)內部形成(cheng)的(de)拉伸應(ying)(ying)力(li)共(gong)同作用下,使(shi)焊(han)(han)接(jie)(jie)接(jie)(jie)頭(tou)產生熱(re)裂(lie)紋(wen)。

2. 焊接(jie)方法

由于(yu)在現(xian)場施工,工作(zuo)條(tiao)(tiao)件比較惡劣,選用(yong)(yong)(yong)焊(han)(han)條(tiao)(tiao)電弧焊(han)(han)用(yong)(yong)(yong)T107(ECu型號)焊(han)(han)條(tiao)(tiao)在06Cr18Ni11Ti 不銹鋼管(guan)(guan)坡口側及其附近堆焊(han)(han)過渡層,然后采(cai)用(yong)(yong)(yong)氧乙炔焊(han)(han)用(yong)(yong)(yong)HS224(HSCuZn-4)焊(han)(han)絲配(pei)合氣焊(han)(han)焊(han)(han)劑硼砂(CJ301)將過渡層的堆焊(han)(han)處與(yu)黃(huang)銅管(guan)(guan)焊(han)(han)接,形成所需要的管(guan)(guan)路。

3. 焊接工藝

焊(han)(han)接(jie)(jie)坡口形(xing)式(shi)如圖(tu)5-46所示,為角接(jie)(jie)接(jie)(jie)頭對接(jie)(jie)焊(han)(han)縫(feng)形(xing)式(shi)。施焊(han)(han)前(qian)要將(jiang)管(guan)路待焊(han)(han)處(chu)的坡口及(ji)其附近用磨光機打磨直至露出金屬光澤。裝配時要留有3~5mm間隙(對接(jie)(jie)接(jie)(jie)頭處(chu)),以保證(zheng)第(di)一(yi)層焊(han)(han)縫(feng)施焊(han)(han)背面成形(xing)良好,避(bi)免出現未焊(han)(han)透和未熔合(he)等(deng)缺(que)陷。

過渡層(ceng)(ceng)(ceng)堆(dui)焊(han)時(shi),在打磨干凈(jing)的(de)06Cr18Ni11Ti不銹鋼管(guan)(guan)坡口待焊(han)處,用(yong)ф3.2mmT107焊(han)條(tiao)堆(dui)焊(han)一層(ceng)(ceng)(ceng)純銅(tong)過渡層(ceng)(ceng)(ceng),然(ran)后再(zai)(zai)從管(guan)(guan)外表(biao)面向(xiang)坡口兩邊堆(dui)焊(han)三道(dao)。純銅(tong)過渡層(ceng)(ceng)(ceng)要堆(dui)焊(han)兩層(ceng)(ceng)(ceng),厚度為5~6mm。然(ran)后用(yong)角向(xiang)打磨機打磨,使表(biao)面干凈(jing)光滑。用(yong)氧乙炔焊(han),Φ4mm的(de)HS224焊(han)絲配(pei)合氣焊(han)焊(han)劑CJ301在堆(dui)焊(han)純銅(tong)層(ceng)(ceng)(ceng)表(biao)面再(zai)(zai)堆(dui)焊(han)一層(ceng)(ceng)(ceng)黃銅(tong)過渡層(ceng)(ceng)(ceng),使其表(biao)面層(ceng)(ceng)(ceng)金屬(shu)與黃銅(tong)(H62)管(guan)(guan)的(de)化學(xue)成分相當。

因結(jie)構形(xing)式無法轉(zhuan)動進行施(shi)(shi)焊(han)(han),故先在相應于(yu)(yu)時鐘(zhong)12、3、9點鐘(zhong)位置(zhi)(zhi)放置(zhi)(zhi)定位焊(han)(han)點。選用HS224焊(han)(han)絲(si),氣焊(han)(han)焊(han)(han)劑CJ301,采用氧乙炔焊(han)(han)進行定位焊(han)(han),然后進行主焊(han)(han)縫施(shi)(shi)焊(han)(han)。在45°夾角處(chu)位置(zhi)(zhi)難于(yu)(yu)焊(han)(han)接時,若(ruo)有可能,可將該(gai)端頭(tou)待焊(han)(han)處(chu)適當(dang)抬(tai)起,使(shi)它處(chu)于(yu)(yu)近似(si)船(chuan)形(xing)焊(han)(han)的(de)位置(zhi)(zhi),便于(yu)(yu)施(shi)(shi)焊(han)(han)。