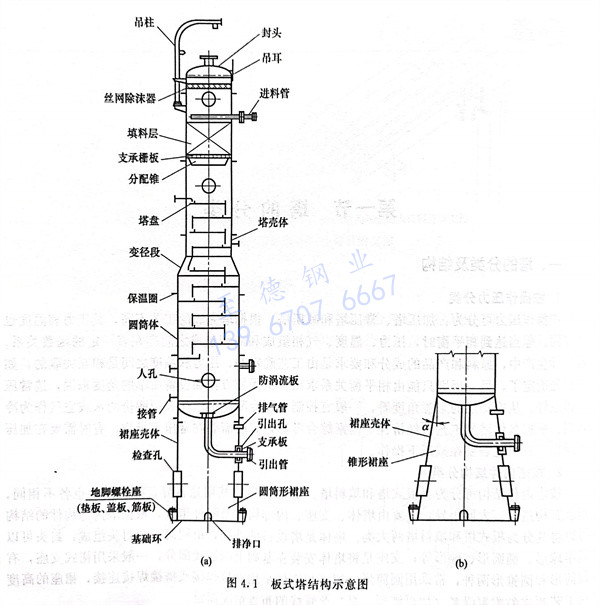

按塔(ta)(ta)內件(jian)(jian)結(jie)構(gou)可(ke)分為(wei):板式(shi)塔(ta)(ta)和(he)填料塔(ta)(ta)。塔(ta)(ta)設備盡管(guan)其用途各異,操作條(tiao)件(jian)(jian)也各不(bu)相同,但就其構(gou)造而言大同小(xiao)異,主要(yao)由塔(ta)(ta)體(ti)(ti)、支(zhi)座(zuo)(zuo)、內部構(gou)件(jian)(jian)及附件(jian)(jian)組成。根據(ju)塔(ta)(ta)內部構(gou)件(jian)(jian)的(de)(de)結(jie)構(gou)可(ke)以(yi)將(jiang)其分為(wei)板式(shi)塔(ta)(ta)和(he)填料塔(ta)(ta)兩大類。塔(ta)(ta)體(ti)(ti)是(shi)塔(ta)(ta)設備的(de)(de)外殼,由圓筒和(he)兩封頭(tou)組成;封頭(tou)可(ke)以(yi)是(shi)半球(qiu)形(xing)(xing)(xing)、橢圓形(xing)(xing)(xing)、碟形(xing)(xing)(xing)等;支(zhi)座(zuo)(zuo)是(shi)將(jiang)塔(ta)(ta)體(ti)(ti)安(an)裝在基礎上的(de)(de)連(lian)接部分,一(yi)般采用裙(qun)式(shi)支(zhi)座(zuo)(zuo),有(you)圓筒形(xing)(xing)(xing)和(he)圓錐形(xing)(xing)(xing)兩種,常(chang)采用圓筒形(xing)(xing)(xing)。裙(qun)座(zuo)(zuo)與塔(ta)(ta)體(ti)(ti)采用對接焊(han)(han)接或搭接焊(han)(han)接連(lian)接,裙(qun)座(zuo)(zuo)的(de)(de)高度(du)由工藝(yi)要(yao)求(qiu)的(de)(de)附屬設備(如再沸(fei)器、泵)及管(guan)線的(de)(de)布置情況而定。

1. 板式塔(plate column)

在(zai)板(ban)式(shi)(shi)(shi)塔(ta)(ta)中裝有(you)一定(ding)數量的塔(ta)(ta)盤(pan)(pan)(pan),液(ye)體(ti)借自身的重(zhong)量自上(shang)(shang)而下沉向(xiang)塔(ta)(ta)底(在(zai)塔(ta)(ta)盤(pan)(pan)(pan)板(ban)上(shang)(shang)沿塔(ta)(ta)徑橫(heng)向(xiang)流動),氣體(ti)靠壓差自下而上(shang)(shang)以鼓泡的形式(shi)(shi)(shi)穿過塔(ta)(ta)盤(pan)(pan)(pan)上(shang)(shang)的液(ye)層(ceng)(ceng)升向(xiang)塔(ta)(ta)頂。在(zai)每層(ceng)(ceng)塔(ta)(ta)盤(pan)(pan)(pan)上(shang)(shang)氣、液(ye)兩相(xiang)密切接觸,進行傳質,使兩相(xiang)的組分濃(nong)度沿塔(ta)(ta)高呈階梯式(shi)(shi)(shi)變化,如圖4.1所(suo)示。

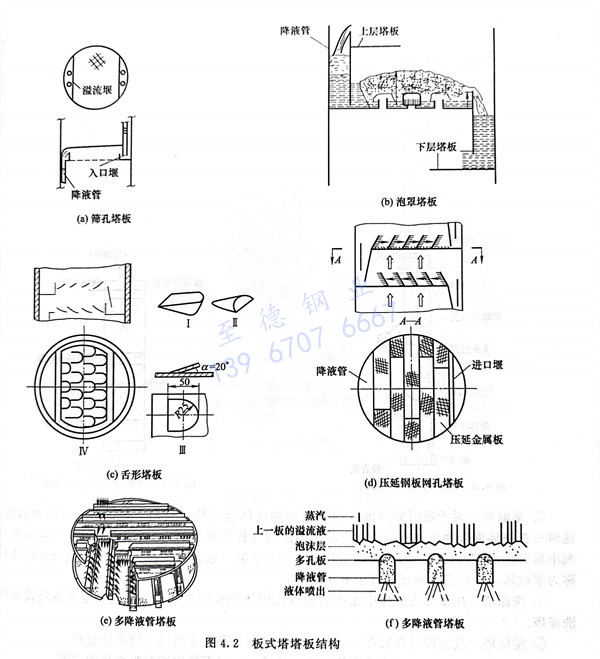

如(ru)果按其(qi)塔板(ban)上氣(qi)、液流向不同還可(ke)分為以(yi)下幾種。

①. 氣(qi)、液(ye)(ye)(ye)(ye)呈(cheng)錯流(liu)(liu)的塔板(ban)(ban)(ban)。氣(qi)、液(ye)(ye)(ye)(ye)呈(cheng)錯流(liu)(liu)的塔板(ban)(ban)(ban)上裝有降(jiang)液(ye)(ye)(ye)(ye)管(guan),液(ye)(ye)(ye)(ye)體(ti)自(zi)上板(ban)(ban)(ban)的降(jiang)液(ye)(ye)(ye)(ye)管(guan)落下,進(jin)入塔板(ban)(ban)(ban)之后(hou),沿著塔板(ban)(ban)(ban)橫向流(liu)(liu)過(guo)(guo),經塔板(ban)(ban)(ban)的降(jiang)液(ye)(ye)(ye)(ye)管(guan)流(liu)(liu)入下一(yi)塊塔板(ban)(ban)(ban)(受(shou)液(ye)(ye)(ye)(ye)槽(cao))。一(yi)般受(shou)液(ye)(ye)(ye)(ye)槽(cao)和對應降(jiang)液(ye)(ye)(ye)(ye)管(guan)寬度是一(yi)樣(yang)的。而(er)氣(qi)體(ti)則(ze)通(tong)過(guo)(guo)塔板(ban)(ban)(ban)的開孔,與液(ye)(ye)(ye)(ye)體(ti)呈(cheng)錯流(liu)(liu)方式傳質(zhi)和傳熱。氣(qi)、液(ye)(ye)(ye)(ye)呈(cheng)錯流(liu)(liu)方式的塔板(ban)(ban)(ban)在生(sheng)產上用得最多,根據其氣(qi)、液(ye)(ye)(ye)(ye)接觸元(yuan)件(jian)形(xing)式的不同,又可分(fen)為泡罩型(xing)塔板(ban)(ban)(ban)、篩孔型(xing)塔板(ban)(ban)(ban)、浮(fu)閥型(xing)塔板(ban)(ban)(ban)和噴射(she)型(xing)塔板(ban)(ban)(ban)。

②. 氣、液呈逆(ni)流(liu)的塔(ta)板(ban)。塔(ta)板(ban)結(jie)構簡(jian)單,不設(she)溢(yi)流(liu)管,氣、液從塔(ta)板(ban)縫中上下穿流(liu)而過,在板(ban)上的流(liu)體為上升蒸汽所攪動而形(xing)成泡沫,進行兩相間(jian)的傳質,這類塔(ta)板(ban)的塔(ta)有柵板(ban)塔(ta)、穿流(liu)式波紋篩板(ban)塔(ta)。

③. 氣(qi)(qi)、液(ye)呈(cheng)并流(liu)(liu)的塔板。氣(qi)(qi)、液(ye)呈(cheng)并流(liu)(liu)的塔板在(zai)每一塊塔板上(shang),氣(qi)(qi)、液(ye)呈(cheng)并流(liu)(liu)接(jie)觸(chu)方(fang)式,對整個塔氣(qi)(qi)、液(ye)呈(cheng)逆流(liu)(liu)操作方(fang)式。

板(ban)(ban)(ban)(ban)式(shi)(shi)塔(ta)(ta)(ta)按有(you)無降(jiang)液(ye)(ye)管塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)可分為兩類:有(you)降(jiang)液(ye)(ye)管塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)(錯流(liu)式(shi)(shi)),包(bao)括篩(shai)(shai)(shai)板(ban)(ban)(ban)(ban)、浮閥板(ban)(ban)(ban)(ban)、泡罩(zhao)板(ban)(ban)(ban)(ban)、導向篩(shai)(shai)(shai)板(ban)(ban)(ban)(ban)、舌形(xing)板(ban)(ban)(ban)(ban)、多降(jiang)液(ye)(ye)管塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)等(deng);無降(jiang)液(ye)(ye)管塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)(逆流(liu)式(shi)(shi)),包(bao)括穿(chuan)(chuan)流(liu)篩(shai)(shai)(shai)板(ban)(ban)(ban)(ban)、穿(chuan)(chuan)流(liu)柵(zha)板(ban)(ban)(ban)(ban)、波紋穿(chuan)(chuan)流(liu)塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)等(deng)。板(ban)(ban)(ban)(ban)式(shi)(shi)塔(ta)(ta)(ta)的結構(gou)板(ban)(ban)(ban)(ban)式(shi)(shi)塔(ta)(ta)(ta)的主要部件是塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban),塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)有(you)許多形(xing)式(shi)(shi)。圖4.2所示為板(ban)(ban)(ban)(ban)式(shi)(shi)塔(ta)(ta)(ta)塔(ta)(ta)(ta)板(ban)(ban)(ban)(ban)結構(gou)。

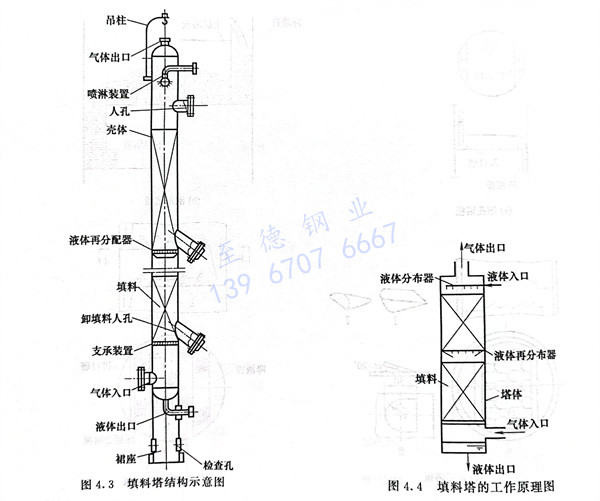

2. 填料塔(packed column)

填(tian)(tian)料(liao)塔(ta)中裝填(tian)(tian)一定高度的(de)填(tian)(tian)料(liao),液(ye)(ye)體(ti)自(zi)塔(ta)頂沿(yan)(yan)填(tian)(tian)料(liao)表面向(xiang)下流動,作為連續(xu)相的(de)氣(qi)體(ti)自(zi)塔(ta)底向(xiang)上流動,與液(ye)(ye)體(ti)進行(xing)逆流,兩相組分的(de)濃度沿(yan)(yan)塔(ta)高呈(cheng)連續(xu)變化。可根據工(gong)藝(yi)特(te)點、介質的(de)特(te)性選用不同類型的(de)填(tian)(tian)料(liao),如拉西(xi)環、鮑爾環等(deng)。填(tian)(tian)料(liao)塔(ta)結(jie)構示意圖如圖4.3所示。

典型填(tian)料(liao)塔(ta)(ta)的(de)(de)工作原理圖(tu)如(ru)圖(tu)4.4所示。塔(ta)(ta)體為一圓筒,筒內堆放一定高度的(de)(de)填(tian)料(liao)。操作時,液(ye)體自(zi)塔(ta)(ta)上部(bu)進(jin)入(ru),通(tong)過(guo)液(ye)體分(fen)布(bu)(bu)器均(jun)勻噴(pen)灑于塔(ta)(ta)截面(mian)上,在(zai)填(tian)料(liao)表(biao)面(mian)呈膜狀流下。填(tian)充高度較高的(de)(de)填(tian)料(liao)塔(ta)(ta)可將填(tian)料(liao)分(fen)層(ceng),各層(ceng)填(tian)料(liao)之間(jian)設置液(ye)體再分(fen)布(bu)(bu)器,收集上層(ceng)流下的(de)(de)液(ye)體,并將液(ye)體重新均(jun)布(bu)(bu)于塔(ta)(ta)截面(mian)。氣(qi)體自(zi)塔(ta)(ta)下部(bu)進(jin)入(ru),通(tong)過(guo)填(tian)料(liao)層(ceng)中的(de)(de)空隙(xi)由塔(ta)(ta)頂排出,離開(kai)填(tian)料(liao)層(ceng)的(de)(de)氣(qi)體可能挾帶少量液(ye)沫,必要時可在(zai)塔(ta)(ta)頂安裝除沫器。