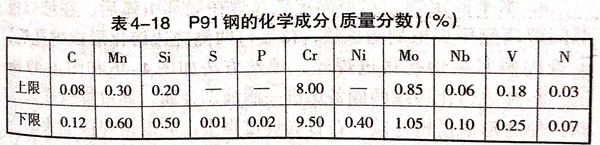

1. P91鋼的(de)化學成(cheng)分

P91鋼為馬氏(shi)體耐熱鋼,其化學成分見(jian)表4-18.

2. 焊(han)前(qian)準備

對口裝(zhuang)配應支(zhi)(zhi)撐(cheng)(cheng)牢固(gu)(gu),防(fang)止(zhi)在焊接(jie)過程中發生管(guan)(guan)道(dao)位移和變形。嚴(yan)禁(jin)在管(guan)(guan)道(dao)母材上(shang)焊接(jie)其他支(zhi)(zhi)撐(cheng)(cheng)物。支(zhi)(zhi)撐(cheng)(cheng)物應遠離加(jia)熱器300~500mm.對口間隙4~5mm,鈍邊≤2mm.點(dian)(dian)固(gu)(gu)時采用同種材料點(dian)(dian)固(gu)(gu)塊,長度為10~20mm,用電焊點(dian)(dian)固(gu)(gu)到P91管(guan)(guan)坡口內,待打底層完(wan)成后(hou)再用角磨機磨掉(diao)。

試(shi)件(jian)(jian)組對前用半圓銼將(jiang)毛刺(ci)打(da)磨(mo)掉,然(ran)后銼出所(suo)需鈍邊。清除試(shi)件(jian)(jian)坡口(kou)周(zhou)圍(wei)20mm范圍(wei)內鐵銹、油污等(deng)。

采用有(you)效(xiao)的充氬(ya)氣保護(hu)措施(shi),在P91大管600mm長度范(fan)圍(wei)內,焊縫間隙用錫(xi)箔紙封(feng)死,管端用草紙板(ban)密閉封(feng)堵成一個氣池,在300℃時草紙板(ban)焦(jiao)煳,760℃高溫回火后,草紙板(ban)變為灰燼,不會造成危(wei)害(hai)。

3. 焊接

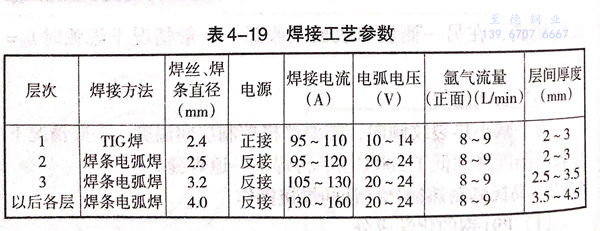

焊(han)(han)接方(fang)法采(cai)用(yong)手工TIG焊(han)(han)打底(di)和焊(han)(han)條電弧焊(han)(han)填充蓋面。對于(yu)水(shui)平(ping)固(gu)定(ding)管始焊(han)(han)位置在時鐘6點位置,焊(han)(han)接方(fang)向(xiang)由底(di)向(xiang)上分兩(liang)半圈進行焊(han)(han)接,可(ke)先從逆時針(zhen)方(fang)向(xiang)開始。對于(yu)垂直固(gu)定(ding)管起(qi)焊(han)(han)位置不作要求。焊(han)(han)接工藝參數見表4-19.

①. 氬(ya)弧焊打底焊

a. 水平固定焊

水平固定氬弧焊(han)(han)(han)(han)(han)在底部(bu)引弧后(hou),在坡口(kou)根部(bu)間隙(xi)兩側(ce)(ce)用焊(han)(han)(han)(han)(han)槍(qiang)劃圈預熱,待(dai)坡口(kou)兩側(ce)(ce)鈍(dun)邊熔(rong)化形成熔(rong)孔后(hou),由管內側(ce)(ce)緊(jin)貼(tie)熔(rong)孔送(song)進(jin)焊(han)(han)(han)(han)(han)絲,填絲方(fang)(fang)法(fa)如圖(tu)4-46和圖(tu)4-47所示。在鈍(dun)邊熔(rong)化邊緣兩側(ce)(ce)各送(song)進(jin)一滴液態金屬,通(tong)過(guo)(guo)焊(han)(han)(han)(han)(han)槍(qiang)橫向(xiang)擺(bai)動,使(shi)之形成搭橋連接。在打底焊(han)(han)(han)(han)(han)過(guo)(guo)程中,應根據焊(han)(han)(han)(han)(han)接位置的(de)不同變換(huan)填絲方(fang)(fang)式。在仰(yang)焊(han)(han)(han)(han)(han)及仰(yang)爬坡焊(han)(han)(han)(han)(han)位置采用內填絲法(fa),在立焊(han)(han)(han)(han)(han)、立爬坡焊(han)(han)(han)(han)(han)及平焊(han)(han)(han)(han)(han)位置時(shi)采用外(wai)填絲法(fa);焊(han)(han)(han)(han)(han)絲與管外(wai)壁焊(han)(han)(han)(han)(han)接方(fang)(fang)向(xiang)成10°~15°夾角。打底焊(han)(han)(han)(han)(han)時(shi)注意(yi)焊(han)(han)(han)(han)(han)槍(qiang)及焊(han)(han)(han)(han)(han)絲擺(bai)動方(fang)(fang)法(fa),一般以鋸齒或月牙擺(bai)動為宜(yi)(圖(tu)4-48).電(dian)弧熔(rong)化坡口(kou)每側(ce)(ce)0.5~1mm,焊(han)(han)(han)(han)(han)絲送(song)進(jin)要緊(jin)貼(tie)熔(rong)池,焊(han)(han)(han)(han)(han)絲端部(bu)跟電(dian)弧行走(zou)方(fang)(fang)向(xiang)做小幅度(du)橫向(xiang)擺(bai)動,擺(bai)動中注意(yi)不得使(shi)焊(han)(han)(han)(han)(han)絲與鎢極端部(bu)接觸(chu)。

封口焊時,當(dang)電弧運至距(ju)管子頂部3~4mm處(chu),停止送(song)絲(si),先在封口處(chu)周圍劃(hua)圈(quan)預熱(re),使(shi)之呈紅熱(re)狀態,然后(hou)將(jiang)電弧拉回原熔池填絲(si)焊接。封口后(hou)停止送(song)絲(si)繼續向前施焊5~10mm停弧。停弧后(hou)不要立即移開(kai)焊槍,要待熔池凝(ning)固后(hou)再移開(kai)。

后半部焊(han)接按順(shun)時針方向焊(han)接,焊(han)接方法與(yu)前(qian)半圈相(xiang)同。打(da)底焊(han)縫(feng)厚(hou)度(du)一般以2~2.5mm為宜(yi)。

b. 垂直(zhi)固定焊

垂直(zhi)固(gu)定氬弧(hu)焊(han)(han)(han)(han)在(zai)(zai)(zai)(zai)坡(po)(po)口(kou)內側空(kong)間引弧(hu),焊(han)(han)(han)(han)槍(qiang)與焊(han)(han)(han)(han)接(jie)方(fang)向(xiang)夾角為(wei)70°~80°,焊(han)(han)(han)(han)絲(si)與管(guan)壁(bi)內側周向(xiang)夾角為(wei)10°~15°,將焊(han)(han)(han)(han)槍(qiang)在(zai)(zai)(zai)(zai)坡(po)(po)口(kou)根(gen)部(bu)做上(shang)(shang)、下劃(hua)圈預熱。當鈍邊熔(rong)化形(xing)(xing)成(cheng)熔(rong)孔后,即在(zai)(zai)(zai)(zai)坡(po)(po)口(kou)根(gen)部(bu)上(shang)(shang)、下側各送一(yi)(yi)滴液態(tai)金屬(shu),擺動焊(han)(han)(han)(han)槍(qiang)形(xing)(xing)成(cheng)搭橋連接(jie),然后開始正(zheng)常焊(han)(han)(han)(han)接(jie)。填充時(shi)應注意焊(han)(han)(han)(han)絲(si)端(duan)部(bu)從上(shang)(shang)側坡(po)(po)口(kou)斜(xie)拉(la)下側坡(po)(po)口(kou)根(gen)部(bu),保證(zheng)電(dian)弧(hu)一(yi)(yi)半用來熔(rong)化金屬(shu),使之形(xing)(xing)成(cheng)均(jun)勻焊(han)(han)(han)(han)縫;一(yi)(yi)半用來打開熔(rong)孔,保證(zheng)背面焊(han)(han)(han)(han)縫成(cheng)形(xing)(xing)。垂直(zhi)固(gu)定管(guan)打底焊(han)(han)(han)(han)時(shi),受重力(li)作用,液態(tai)金屬(shu)極易下墜(zhui),因此在(zai)(zai)(zai)(zai)操作時(shi)送絲(si)要節(jie)奏均(jun)勻,焊(han)(han)(han)(han)槍(qiang)采(cai)用上(shang)(shang)、下斜(xie)拉(la)鋸齒形(xing)(xing)擺動方(fang)法,盡(jin)量采(cai)用短(duan)弧(hu)焊(han)(han)(han)(han)接(jie)。

②. 焊(han)條電弧焊(han)填(tian)充及蓋面(mian)焊(han)

a. 水平固定焊(han)

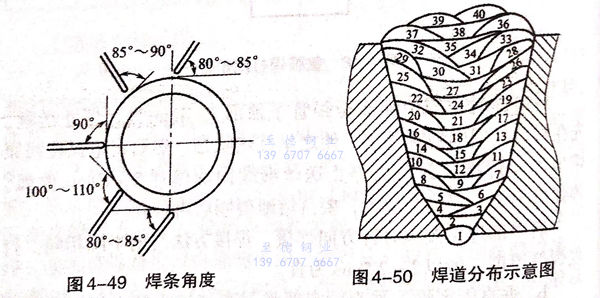

水平固(gu)定管填(tian)(tian)充(chong)及蓋面焊(han)均采用(yong)焊(han)條(tiao)電弧焊(han),通常(chang)是(shi)將(jiang)打底焊(han)前半部分作為填(tian)(tian)充(chong)焊(han)的(de)后半部分,目的(de)是(shi)將(jiang)上(shang)下接頭錯開,填(tian)(tian)充(chong)層運(yun)條(tiao)采用(yong)鋸(ju)齒形擺(bai)動,在(zai)焊(han)接過程中,從下向上(shang)焊(han)接位置(zhi)不得變化,焊(han)條(tiao)角度也應隨之(zhi)發(fa)生變化,如(ru)圖4-49所示(shi)。

蓋面層(ceng)采用(yong)月牙形運條焊接,在坡口(kou)兩側(ce)邊緣要注(zhu)意停頓。焊條擺動要平(ping)(ping)穩,以使(shi)焊后波紋均(jun)勻美(mei)觀。引弧點(dian)要在焊接前方10~15mm處,電(dian)弧引燃后,要拉回熔池中心處,待弧坑(keng)填滿后,方能(neng)繼(ji)續向(xiang)前擺動焊接。水平(ping)(ping)固定管焊道(dao)布置如圖(tu)4-50所示。

b. 垂直固定焊(han)

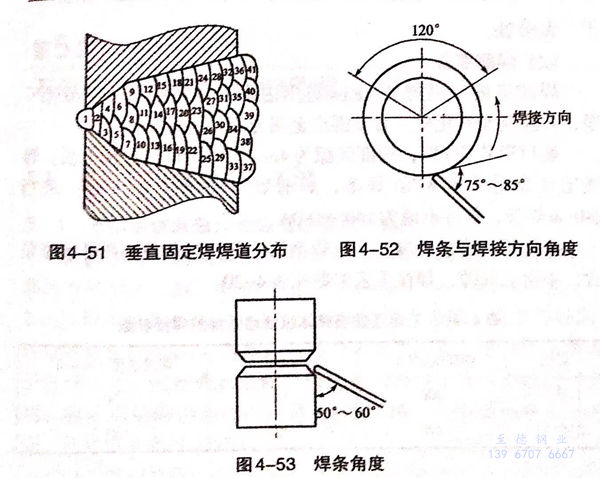

垂直固定管焊(han)(han)(han)(han)(han)(han)接時(shi)(shi)(shi),必(bi)須保證焊(han)(han)(han)(han)(han)(han)縫(feng)上下兩(liang)端(duan)熔合(he)良好,不得出(chu)現未熔合(he)和夾渣(zha)等缺陷。填充焊(han)(han)(han)(han)(han)(han)道(dao)采用(yong)多道(dao)焊(han)(han)(han)(han)(han)(han),焊(han)(han)(han)(han)(han)(han)道(dao)分布(bu)如圖4-51所示。焊(han)(han)(han)(han)(han)(han)條(tiao)角(jiao)(jiao)(jiao)度(du)如圖4-52和圖4-53所示。第(di)一(yi)(yi)(yi)道(dao)焊(han)(han)(han)(han)(han)(han)時(shi)(shi)(shi)焊(han)(han)(han)(han)(han)(han)條(tiao)與焊(han)(han)(han)(han)(han)(han)接方向(xiang)的(de)夾角(jiao)(jiao)(jiao)為(wei)(wei)75°~85°,與坡(po)(po)口下端(duan)夾角(jiao)(jiao)(jiao)為(wei)(wei)50°~60°,運(yun)(yun)條(tiao)方法(fa)為(wei)(wei)斜圓圈形。焊(han)(han)(han)(han)(han)(han)接過(guo)程中注意電(dian)弧(hu)中心對(dui)準上一(yi)(yi)(yi)層焊(han)(han)(han)(han)(han)(han)縫(feng)的(de)下邊(bian)(bian)緣(yuan),向(xiang)前運(yun)(yun)條(tiao)時(shi)(shi)(shi)不要(yao)將坡(po)(po)口棱(leng)邊(bian)(bian)破壞(huai),以(yi)防蓋(gai)(gai)面焊(han)(han)(han)(han)(han)(han)時(shi)(shi)(shi)影響視線。下一(yi)(yi)(yi)道(dao)焊(han)(han)(han)(han)(han)(han)對(dui)準上一(yi)(yi)(yi)道(dao)焊(han)(han)(han)(han)(han)(han)縫(feng)的(de)上邊(bian)(bian)緣(yuan),但焊(han)(han)(han)(han)(han)(han)條(tiao)角(jiao)(jiao)(jiao)度(du)向(xiang)下適當調整。運(yun)(yun)條(tiao)時(shi)(shi)(shi)注意電(dian)弧(hu)覆蓋(gai)(gai)焊(han)(han)(han)(han)(han)(han)道(dao)情況,下側要(yao)稍(shao)大于上一(yi)(yi)(yi)道(dao)焊(han)(han)(han)(han)(han)(han)縫(feng)中心,上側要(yao)緊貼坡(po)(po)口邊(bian)(bian)緣(yuan)棱(leng)角(jiao)(jiao)(jiao)處。

蓋面焊時第(di)一(yi)(yi)道(dao)采(cai)用直(zhi)線形(xing)(xing)運(yun)(yun)條(tiao)(tiao),短(duan)弧焊接(jie)(jie)。焊接(jie)(jie)中注意坡口下(xia)邊緣熔(rong)(rong)化情(qing)況,一(yi)(yi)般熔(rong)(rong)池要熔(rong)(rong)化坡口邊緣0.5~1mm.下(xia)一(yi)(yi)道(dao)焊接(jie)(jie)采(cai)用斜圓圈形(xing)(xing)運(yun)(yun)條(tiao)(tiao)方法,要壓住上(shang)一(yi)(yi)道(dao)焊縫近2/3.焊條(tiao)(tiao)擺動(dong)幅度(du)要視所剩焊縫寬(kuan)度(du)選擇(ze)。寬(kuan)度(du)大采(cai)用斜鋸齒擺動(dong),寬(kuan)度(du)小(xiao)(xiao)則采(cai)用直(zhi)線運(yun)(yun)條(tiao)(tiao)方法。焊接(jie)(jie)中要適當減小(xiao)(xiao)焊接(jie)(jie)電流,并縮短(duan)弧長,使熔(rong)(rong)化的液態金屬和熔(rong)(rong)渣均勻(yun)覆蓋在(zai)焊縫表面上(shang),得到整(zheng)齊美觀的焊縫成形(xing)(xing)。

4. 焊后熱(re)處理

焊(han)后(hou)(hou)在焊(han)縫(feng)冷至100~120℃后(hou)(hou)進行焊(han)后(hou)(hou)熱(re)處理(li)。焊(han)后(hou)(hou)熱(re)處理(li)的升溫速(su)度控(kong)(kong)制(zhi)(zhi)在150℃以下,恒(heng)溫溫度為750℃±10℃,恒(heng)溫時(shi)間按壁厚每(mei)25mm保溫1h計(ji)算,但不得少于3h,降至300℃以下,可以不作(zuo)控(kong)(kong)制(zhi)(zhi)。