連續軋管機是在毛管內穿入長芯棒后,經過多機架順序布置且相鄰機架輥縫互錯(二輥式輥縫互錯90°如圖4-1所示,三輥式輥縫互錯60°)的連軋機軋成不銹鋼管,它是當今最為廣泛使用的縱軋不銹鋼管方法。在連續軋管機軋制過程中,軋件變形實際上是受多組(4~8組)軋輥與芯棒的反復作用從圓到橢圓···橢圓再到圓的過程。

連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機的(de)發展(zhan)(zhan)歷史悠久,早在(zai)19世(shi)(shi)紀(ji)末就曾嘗試在(zai)長(chang)芯棒(bang)(bang)上(shang)進行軋(ya)(ya)(ya)管(guan)(guan),但由(you)于(yu)種種原因,至1950年(nian)世(shi)(shi)界(jie)上(shang)也僅有6臺連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機。1960年(nian)后,隨著科學技術(shu)(shu)的(de)進步和(he)生產的(de)發展(zhan)(zhan),特別是電子計算機技術(shu)(shu)的(de)飛速發展(zhan)(zhan)和(he)應(ying)用,使(shi)連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機在(zai)生產工(gong)藝和(he)設備上(shang)日趨完善,得到(dao)了(le)迅速的(de)發展(zhan)(zhan)和(he)推廣。在(zai)浮動(dong)芯棒(bang)(bang)連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機的(de)基礎上(shang),限動(dong)芯棒(bang)(bang)連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機于(yu)20世(shi)(shi)紀(ji)60年(nian)代中期進行了(le)工(gong)藝試驗,獲得了(le)可(ke)喜的(de)成果(guo)。1978年(nian)世(shi)(shi)界(jie)上(shang)第(di)一套限動(dong)芯棒(bang)(bang)連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機(MPM)在(zai)意大利(li)達爾明鋼管(guan)(guan)廠(chang)建(jian)成投(tou)產,連續(xu)軋(ya)(ya)(ya)管(guan)(guan)工(gong)藝發展(zhan)(zhan)到(dao)了(le)一個新的(de)水(shui)準。20世(shi)(shi)紀(ji)90年(nian)代末又推出了(le)三輥連續(xu)軋(ya)(ya)(ya)管(guan)(guan)機(PQF)技術(shu)(shu),使(shi)連續(xu)軋(ya)(ya)(ya)管(guan)(guan)工(gong)藝裝備躍上(shang)了(le)更高的(de)臺階。

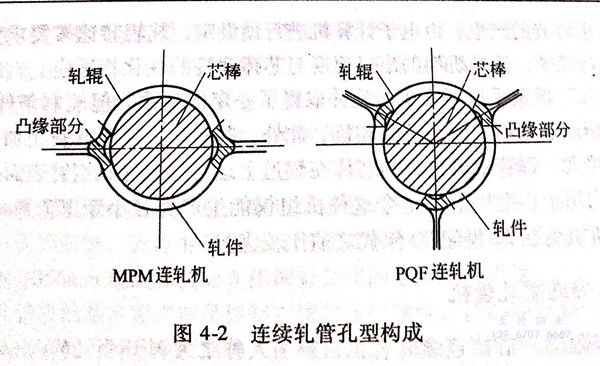

連續(xu)(xu)(xu)軋(ya)管機(ji)在PQF出現以前(qian),都是兩(liang)(liang)輥(gun)式的(de)(de)(de)(de)(de)(de)(de),即由兩(liang)(liang)個(ge)軋(ya)輥(gun)為(wei)一(yi)組組成孔(kong)型,二(er)輥(gun)式的(de)(de)(de)(de)(de)(de)(de)機(ji)架(jia)既有(you)(you)與(yu)(yu)地面呈45°交錯(cuo)布(bu)置(zhi)(zhi)的(de)(de)(de)(de)(de)(de)(de),也有(you)(you)與(yu)(yu)地面垂直、水平交錯(cuo)布(bu)置(zhi)(zhi)的(de)(de)(de)(de)(de)(de)(de)。PQF為(wei)三輥(gun)式的(de)(de)(de)(de)(de)(de)(de),即由三個(ge)軋(ya)輥(gun)為(wei)一(yi)組組成孔(kong)型,如圖4-2所(suo)示。連續(xu)(xu)(xu)軋(ya)管時,孔(kong)型頂部(bu)的(de)(de)(de)(de)(de)(de)(de)金屬(shu)由于受(shou)到軋(ya)輥(gun)外壓力和芯棒(bang)(bang)內壓力作用而產(chan)生軸(zhou)(zhou)(zhou)向(xiang)(xiang)延伸(shen)(shen),并向(xiang)(xiang)圓周橫向(xiang)(xiang)寬(kuan)展,而孔(kong)型側壁部(bu)分的(de)(de)(de)(de)(de)(de)(de)金屬(shu)與(yu)(yu)芯棒(bang)(bang)不(bu)接觸(chu),但它(ta)被頂部(bu)軸(zhou)(zhou)(zhou)向(xiang)(xiang)延伸(shen)(shen)的(de)(de)(de)(de)(de)(de)(de)金屬(shu)對它(ta)附加的(de)(de)(de)(de)(de)(de)(de)拉應力作用而產(chan)生軸(zhou)(zhou)(zhou)向(xiang)(xiang)延伸(shen)(shen),并同時產(chan)生軸(zhou)(zhou)(zhou)向(xiang)(xiang)拉縮。不(bu)論兩(liang)(liang)輥(gun)式的(de)(de)(de)(de)(de)(de)(de)還是三輥(gun)式的(de)(de)(de)(de)(de)(de)(de)連續(xu)(xu)(xu)軋(ya)管機(ji),按芯棒(bang)(bang)的(de)(de)(de)(de)(de)(de)(de)運行方式可分為(wei)浮(fu)動(dong)芯棒(bang)(bang)連續(xu)(xu)(xu)軋(ya)管機(ji)、半浮(fu)動(dong)芯棒(bang)(bang)連續(xu)(xu)(xu)軋(ya)管機(ji)和限動(dong)芯棒(bang)(bang)連續(xu)(xu)(xu)軋(ya)管機(ji)三種形式。

為了完(wan)成(cheng)將連續軋管(guan)機(ji)軋出的荒管(guan)與芯棒(bang)脫開分離的工(gong)藝目的,便于荒管(guan)在后道工(gong)序進(jin)一步加工(gong)成(cheng)品不銹(xiu)鋼(gang)管(guan),一般采用以下兩種方法。

1. 脫棒機(ji)

軋(ya)(ya)制(zhi)結束(shu)后荒(huang)管(guan)(guan)(guan)/芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)被一起(qi)移(yi)出(chu)軋(ya)(ya)制(zhi)線(xian),荒(huang)管(guan)(guan)(guan)受軸向約束(shu)不動(dong),用裝(zhuang)(zhuang)置(zhi)(zhi)將(jiang)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)從荒(huang)管(guan)(guan)(guan)中(zhong)抽(chou)出(chu)。我(wo)們將(jiang)這種荒(huang)管(guan)(guan)(guan)不動(dong),芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)動(dong)的(de)(de)設備稱為脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)機。當(dang)帶(dai)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)的(de)(de)荒(huang)管(guan)(guan)(guan)進(jin)入脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)位(wei)(wei)(wei)置(zhi)(zhi)后,脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian)上(shang)的(de)(de)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)卡(ka)緊(jin)裝(zhuang)(zhuang)置(zhi)(zhi)就鉤(gou)住芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)的(de)(de)尾柄(bing),而液(ye)壓(ya)開閉的(de)(de)卡(ka)板(ban)擋(dang)(dang)住荒(huang)管(guan)(guan)(guan),脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian)從荒(huang)管(guan)(guan)(guan)中(zhong)抽(chou)出(chu)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)。脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian)轉過半(ban)圈完成(cheng)一次(ci)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)動(dong)作,鏈(lian)所走過的(de)(de)距(ju)離約為芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)長(chang)度(du)的(de)(de)1.1倍。脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)機的(de)(de)最大速度(du)大于(yu)4.5m/s,到達終位(wei)(wei)(wei)的(de)(de)誤差為±50mm.脫(tuo)(tuo)(tuo)(tuo)(tuo)出(chu)的(de)(de)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)經輸送輥道送到芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)定位(wei)(wei)(wei)升降擋(dang)(dang)板(ban)前,然后由芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)移(yi)送裝(zhuang)(zhuang)置(zhi)(zhi)把芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)送人芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)冷卻槽(cao),循環使用。脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)機安裝(zhuang)(zhuang)位(wei)(wei)(wei)置(zhi)(zhi)與連(lian)續軋(ya)(ya)管(guan)(guan)(guan)機平行。脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)機有兩(liang)(liang)(liang)列脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian),這兩(liang)(liang)(liang)列脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian)用橫梁(liang)連(lian)接起(qi)來(lai),兩(liang)(liang)(liang)列脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)鏈(lian)間共有兩(liang)(liang)(liang)個脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)橫梁(liang)及多個承(cheng)載橫梁(liang)。脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)橫梁(liang)用來(lai)從荒(huang)管(guan)(guan)(guan)中(zhong)抽(chou)出(chu)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang),而承(cheng)載橫梁(liang)用來(lai)在(zai)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)過程中(zhong)支撐芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)。在(zai)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)橫梁(liang)上(shang)用螺(luo)栓緊(jin)固(gu)與軋(ya)(ya)件(jian)尺寸相關的(de)(de)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)卡(ka)緊(jin)裝(zhuang)(zhuang)置(zhi)(zhi),當(dang)更(geng)換(huan)軋(ya)(ya)制(zhi)芯(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)(bang)(bang)(bang)時,需要更(geng)換(huan)脫(tuo)(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)(bang)(bang)(bang)(bang)卡(ka)緊(jin)裝(zhuang)(zhuang)置(zhi)(zhi)。

2. 脫管(guan)機(ji)

軋(ya)(ya)(ya)制(zhi)(zhi)結(jie)束(shu)后,芯(xin)(xin)(xin)(xin)棒(bang)(bang)停止運(yun)動,荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)在(zai)(zai)線被脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)裝置(zhi)(zhi)將(jiang)(jiang)其(qi)(qi)從(cong)(cong)芯(xin)(xin)(xin)(xin)棒(bang)(bang)中(zhong)(zhong)脫(tuo)(tuo)(tuo)(tuo)出(chu),我們將(jiang)(jiang)這種(zhong)芯(xin)(xin)(xin)(xin)棒(bang)(bang)不動,荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)動的(de)(de)(de)(de)設(she)(she)備稱為脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)。脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)既(ji)有(you)(you)(you)兩輥(gun)(gun)(gun)(gun)式的(de)(de)(de)(de),也(ye)有(you)(you)(you)三輥(gun)(gun)(gun)(gun)式的(de)(de)(de)(de)。脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)的(de)(de)(de)(de)設(she)(she)置(zhi)(zhi)有(you)(you)(you)兩個重要(yao)的(de)(de)(de)(de)工(gong)藝(yi)(yi)目的(de)(de)(de)(de):(1)將(jiang)(jiang)荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)從(cong)(cong)芯(xin)(xin)(xin)(xin)棒(bang)(bang)上(shang)脫(tuo)(tuo)(tuo)(tuo)出(chu),完成脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)目的(de)(de)(de)(de),在(zai)(zai)軋(ya)(ya)(ya)制(zhi)(zhi)線上(shang)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan),省去了脫(tuo)(tuo)(tuo)(tuo)棒(bang)(bang)機(ji)(ji)(ji)(ji)(ji),縮短了工(gong)藝(yi)(yi)流程,提高(gao)了終軋(ya)(ya)(ya)溫度(du);(2)起定(ding)(ding)(ding)徑(jing)作用,也(ye)就是說(shuo)在(zai)(zai)每(mei)一(yi)支鋼管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)生產中(zhong)(zhong),該機(ji)(ji)(ji)(ji)(ji)也(ye)有(you)(you)(you)延(yan)伸和(he)(he)定(ding)(ding)(ding)徑(jing)作用。在(zai)(zai)早(zao)期設(she)(she)計的(de)(de)(de)(de)限動芯(xin)(xin)(xin)(xin)棒(bang)(bang)連(lian)續軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)組(zu)中(zhong)(zhong)就嘗(chang)試過不單獨(du)設(she)(she)置(zhi)(zhi)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)(如1985年建造的(de)(de)(de)(de)日(ri)本(ben)NKK京(jing)濱廠的(de)(de)(de)(de)ф250mm機(ji)(ji)(ji)(ji)(ji)組(zu)和(he)(he)1990年建造的(de)(de)(de)(de)俄羅斯(si)伏(fu)爾(er)加(jia)鋼管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)廠的(de)(de)(de)(de)Φ426mm機(ji)(ji)(ji)(ji)(ji)組(zu)),而是將(jiang)(jiang)MPM軋(ya)(ya)(ya)出(chu)的(de)(de)(de)(de)荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)直接送人緊隨其(qi)(qi)后的(de)(de)(de)(de)10機(ji)(ji)(ji)(ji)(ji)架(jia)二輥(gun)(gun)(gun)(gun)式脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)/定(ding)(ding)(ding)徑(jing)機(ji)(ji)(ji)(ji)(ji)組(zu)定(ding)(ding)(ding)徑(jing)(1997年日(ri)本(ben)住友和(he)(he)歌(ge)山ф426mm MPM 機(ji)(ji)(ji)(ji)(ji)組(zu)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)/定(ding)(ding)(ding)徑(jing)機(ji)(ji)(ji)(ji)(ji)組(zu)則是送入(ru)(ru)其(qi)(qi)后的(de)(de)(de)(de)12架(jia)三輥(gun)(gun)(gun)(gun)式(FQS)),使脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)和(he)(he)定(ding)(ding)(ding)徑(jing)在(zai)(zai)一(yi)個工(gong)序內完成;荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)在(zai)(zai)連(lian)續軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)軋(ya)(ya)(ya)制(zhi)(zhi)的(de)(de)(de)(de)同時(shi)(shi),被脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)/定(ding)(ding)(ding)徑(jing)機(ji)(ji)(ji)(ji)(ji)組(zu)從(cong)(cong)芯(xin)(xin)(xin)(xin)棒(bang)(bang)上(shang)脫(tuo)(tuo)(tuo)(tuo)出(chu)并(bing)完成定(ding)(ding)(ding)徑(jing)任(ren)務,實現MPM與定(ding)(ding)(ding)徑(jing)機(ji)(ji)(ji)(ji)(ji)組(zu)之間的(de)(de)(de)(de)連(lian)軋(ya)(ya)(ya)。但由于(yu)(yu)荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)的(de)(de)(de)(de)規格(ge)和(he)(he)材(cai)質種(zhong)類較多,給成品(pin)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)的(de)(de)(de)(de)外(wai)徑(jing)控制(zhi)(zhi)帶(dai)來困難,很難保證鋼管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)的(de)(de)(de)(de)外(wai)徑(jing)精(jing)度(du),因此(ci)在(zai)(zai)以后的(de)(de)(de)(de)機(ji)(ji)(ji)(ji)(ji)組(zu)中(zhong)(zhong)沒有(you)(you)(you)再使用這種(zhong)工(gong)藝(yi)(yi)布置(zhi)(zhi)。為生產薄壁(bi)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)和(he)(he)中(zhong)(zhong)厚壁(bi)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan),每(mei)架(jia)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)的(de)(de)(de)(de)孔型名(ming)義直徑(jing)必須小于(yu)(yu)軋(ya)(ya)(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)芯(xin)(xin)(xin)(xin)棒(bang)(bang)直徑(jing)。在(zai)(zai)生產薄壁(bi)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)時(shi)(shi),脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)的(de)(de)(de)(de)減徑(jing)量要(yao)相(xiang)(xiang)應(ying)加(jia)大,否則薄壁(bi)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)不易被脫(tuo)(tuo)(tuo)(tuo)出(chu)。每(mei)架(jia)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)上(shang)都裝有(you)(you)(you)安全白,以防(fang)止芯(xin)(xin)(xin)(xin)棒(bang)(bang)進入(ru)(ru)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)時(shi)(shi)損傷軋(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)及(ji)相(xiang)(xiang)關的(de)(de)(de)(de)機(ji)(ji)(ji)(ji)(ji)械部分。在(zai)(zai)事(shi)故情況(kuang)下,假如當帶(dai)芯(xin)(xin)(xin)(xin)棒(bang)(bang)的(de)(de)(de)(de)荒(huang)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)進入(ru)(ru)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)孔型時(shi)(shi),若(ruo)脫(tuo)(tuo)(tuo)(tuo)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)機(ji)(ji)(ji)(ji)(ji)軋(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)承受的(de)(de)(de)(de)徑(jing)向載荷(he)大于(yu)(yu)預(yu)設(she)(she)值,則軋(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)孔型會相(xiang)(xiang)應(ying)張開,防(fang)止芯(xin)(xin)(xin)(xin)棒(bang)(bang)頂(ding)壞(huai)軋(ya)(ya)(ya)輥(gun)(gun)(gun)(gun)及(ji)設(she)(she)備。

3. 空減機的配(pei)置

空減機(ji)是空心坯減徑(jing)機(ji)的(de)簡稱,一套連續軋(ya)管(guan)機(ji)為使其(qi)產品外(wai)徑(jing)規格范圍盡(jin)可能(neng)地大,設(she)計時(shi)一般選用2~5個孔型(xing),軋(ya)管(guan)機(ji)后配備張減機(ji)的(de)選擇孔型(xing)數(shu)較(jiao)少,軋(ya)管(guan)機(ji)后配備定徑(jing)機(ji)的(de)選擇孔型(xing)數(shu)較(jiao)多。由于孔型(xing)尺(chi)寸的(de)變化相應地軋(ya)管(guan)機(ji)入(ru)口的(de)毛管(guan)外(wai)徑(jing)也(ye)要隨著發生變化,為適應軋(ya)管(guan)機(ji)入(ru)口毛管(guan)外(wai)徑(jing)變化,通常(chang)有(you)兩種方(fang)法(fa):

a. 選(xuan)用(yong)(yong)幾種外(wai)徑的(de)管坯(pi),針對(dui)不同(tong)的(de)孔型(xing)選(xuan)用(yong)(yong)不同(tong)規格的(de)管坯(pi),但每次(ci)更換孔型(xing)時需對(dui)穿(chuan)孔機(ji)的(de)受料(liao)槽、導衛裝置(導板(ban)或導盤)進行更換,這樣做一方面占用(yong)(yong)較多工作(zuo)時間(jian);另一方面管坯(pi)料(liao)場(chang)(chang)、穿(chuan)孔機(ji)工具需要場(chang)(chang)地較大(da);

b. 在穿孔(kong)機與軋管(guan)機之間(jian)布(bu)置(zhi)一(yi)臺空減機,通(tong)過空減機可(ke)使(shi)用同(tong)一(yi)種外徑尺寸的(de)管(guan)坯來(lai)滿足軋管(guan)機不同(tong)孔(kong)型(xing)成為可(ke)能。

浮(fu)動芯棒連(lian)續軋(ya)管(guan)機(ji)組采用(yong)穿(chuan)孔(kong)(kong)機(ji)與軋(ya)管(guan)機(ji)之間布置(zhi)空減機(ji)的(de)方法(fa)比較經(jing)濟(ji),這樣既可僅用(yong)一個規格的(de)管(guan)坯(pi)(pi)組織生產,減少了管(guan)坯(pi)(pi)庫的(de)面積和穿(chuan)孔(kong)(kong)機(ji)相關的(de)軋(ya)制(zhi)(zhi)工具(ju)數量(liang),又可以減少換(huan)孔(kong)(kong)型的(de)時間,提高了機(ji)組的(de)作業(ye)率。經(jing)空減機(ji)后(hou)的(de)毛管(guan)在運往(wang)連(lian)續軋(ya)管(guan)機(ji)入口臺架前,先(xian)通過(guo)一個吹灰裝置(zhi)用(yong)壓(ya)縮空氣吹去毛管(guan)內(nei)(nei)的(de)細小氧化鐵皮,以減少對(dui)芯棒的(de)磨損(sun)和管(guan)子(zi)內(nei)(nei)表面缺陷,同時空減機(ji)亦消除了狄(di)塞(sai)爾穿(chuan)孔(kong)(kong)機(ji)所造(zao)成的(de)毛管(guan)頭尾外(wai)徑差,使軋(ya)制(zhi)(zhi)過(guo)程穩(wen)定。這種單獨(du)布置(zhi)的(de)空減機(ji)一般使用(yong)三輥式及(ji)3~6個機(ji)架。

半浮動(dong)(dong)芯(xin)棒(bang)連續(xu)軋(ya)(ya)管(guan)機(ji)組將(jiang)空減(jian)(jian)(jian)機(ji)布置在(zai)(zai)連續(xu)軋(ya)(ya)管(guan)機(ji)的(de)人口側,即(ji)與(yu)連續(xu)軋(ya)(ya)管(guan)機(ji)串(chuan)列(lie)布置,一(yi)(yi)般為(wei)兩輥式(shi)、2~4架;在(zai)(zai)保(bao)持了(le)原有(you)空減(jian)(jian)(jian)機(ji)優點(dian)的(de)同時,可縮(suo)短工藝流程,減(jian)(jian)(jian)少(shao)占地面(mian)積(ji)。這(zhe)種變(bian)化一(yi)(yi)方(fang)面(mian)是(shi)因(yin)為(wei)錐形輥穿(chuan)孔機(ji)的(de)應用使變(bian)形前(qian)移,軋(ya)(ya)管(guan)機(ji)的(de)機(ji)架數相應減(jian)(jian)(jian)少(shao)(減(jian)(jian)(jian)少(shao)2~3架),串(chuan)列(lie)布置因(yin)芯(xin)棒(bang)的(de)長度增(zeng)加而引(yin)起的(de)軋(ya)(ya)制節奏(zou)變(bian)化不是(shi)很多(因(yin)軋(ya)(ya)制終了(le)芯(xin)棒(bang)向前(qian)運(yun)動(dong)(dong));另一(yi)(yi)方(fang)面(mian)串(chuan)列(lie)布置可減(jian)(jian)(jian)少(shao)毛管(guan)在(zai)(zai)縱向移動(dong)(dong)過程中內(nei)表面(mian)的(de)氧化和溫降,能更有(you)效地確保(bao)鋼管(guan)質(zhi)量。

限(xian)動(dong)(dong)(dong)(dong)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)連續軋(ya)管(guan)(guan)(guan)機(ji)(ji)組(zu)在最初時沒有(you)空減機(ji)(ji),采用的(de)是(shi)一(yi)種(zhong)規格的(de)管(guan)(guan)(guan)坯對(dui)應一(yi)個孔(kong)(kong)型,這主(zhu)要是(shi)因(yin)為軋(ya)制(zhi)時芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)與(yu)軋(ya)件(jian)內表(biao)面的(de)相(xiang)對(dui)運動(dong)(dong)(dong)(dong)比(bi)浮動(dong)(dong)(dong)(dong)的(de)大,芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)的(de)工作條件(jian)更(geng)(geng)為惡劣,芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)更(geng)(geng)容易磨損(sun)和劃傷。限(xian)動(dong)(dong)(dong)(dong)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)工藝上(shang)不(bu)(bu)允許(xu)毛(mao)(mao)管(guan)(guan)(guan)在進(jin)入軋(ya)管(guan)(guan)(guan)機(ji)(ji)前做縱(zong)向運動(dong)(dong)(dong)(dong),必須有(you)效的(de)防止毛(mao)(mao)管(guan)(guan)(guan)內表(biao)面的(de)二次氧化,才能確保(bao)鋼管(guan)(guan)(guan)的(de)質量,因(yin)此不(bu)(bu)可能像(xiang)浮動(dong)(dong)(dong)(dong)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)那樣在穿(chuan)孔(kong)(kong)機(ji)(ji)與(yu)軋(ya)管(guan)(guan)(guan)機(ji)(ji)之間(jian)布(bu)置(zhi)(zhi)空減機(ji)(ji)。如(ru)采用半浮動(dong)(dong)(dong)(dong)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)的(de)串(chuan)列布(bu)置(zhi)(zhi),因(yin)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)長(chang)(chang)度的(de)增(zeng)加(jia)使軋(ya)制(zhi)節奏(zou)更(geng)(geng)加(jia)緩慢(因(yin)軋(ya)制(zhi)終了芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)向后運動(dong)(dong)(dong)(dong)),將影響機(ji)(ji)組(zu)的(de)產能的(de)發揮,也(ye)是(shi)不(bu)(bu)經濟的(de)。近十年(nian)來(lai),限(xian)動(dong)(dong)(dong)(dong)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)機(ji)(ji)組(zu)也(ye)在不(bu)(bu)斷吸收其(qi)他機(ji)(ji)組(zu)的(de)長(chang)(chang)處(chu),在軋(ya)管(guan)(guan)(guan)機(ji)(ji)入口側串(chuan)列布(bu)置(zhi)(zhi)1架(jia)空減機(ji)(ji)(三輥、四輥形式(shi)均有(you)),目(mu)的(de)在于消除毛(mao)(mao)管(guan)(guan)(guan)內表(biao)面與(yu)芯(xin)(xin)(xin)(xin)(xin)(xin)棒(bang)(bang)(bang)之間(jian)的(de)間(jian)隙和毛(mao)(mao)管(guan)(guan)(guan)外徑(jing)的(de)頭尾直徑(jing)偏(pian)差,使軋(ya)制(zhi)更(geng)(geng)加(jia)平(ping)穩,從(cong)而提高軋(ya)輥的(de)使用壽命,確保(bao)鋼管(guan)(guan)(guan)的(de)幾何(he)尺寸精度和內外表(biao)面質量。

4. 吹硼砂的(de)工藝(yi)

限(xian)動(dong)芯(xin)棒(bang)連續軋(ya)管機(ji)組比(bi)浮動(dong)、半浮動(dong)機(ji)組多了一個工序就是(shi)(shi)在軋(ya)管機(ji)入口前(qian)向毛管內用(yong)氮氣(qi)噴(pen)抗氧(yang)化劑(ji),工藝目(mu)的是(shi)(shi)去除(chu)內表面的氧(yang)化鐵皮并防止二次氧(yang)化。抗氧(yang)化劑(ji)在高溫(wen)時(shi)呈(cheng)熔融狀態可起到很好的潤滑作用(yong),對抗氧(yang)化劑(ji)的成分、顆粒(li)尺寸、化學(xue)穩定性(xing)(xing)、物理穩定性(xing)(xing)及(ji)吹(chui)撒的數量、噴(pen)吹(chui)的壓(ya)力(li)、時(shi)間(jian)都有嚴格的要求,主要是(shi)(shi)解決軋(ya)管機(ji)的延伸大(da)、軋(ya)制(zhi)時(shi)芯(xin)棒(bang)與軋(ya)件(jian)間(jian)相對運動(dong)較大(da)、芯(xin)棒(bang)的工作條件(jian)更為惡劣,芯(xin)棒(bang)更容(rong)易磨損(sun)和劃傷(shang)、潤滑條件(jian)不好時(shi)容(rong)易發生軋(ya)卡(ka)事故或軋(ya)制(zhi)終(zhong)了時(shi)脫管機(ji)不能將荒管從芯(xin)棒(bang)中順利(li)的抽出等問題(ti)。