限(xian)動(dong)(dong)芯(xin)棒(bang)連軋(ya)管(guan)工藝被稱作“Retained mandrel mill”或(huo)“Multi-stand pipe mill”(簡稱MPM),前者是從芯(xin)棒(bang)運(yun)動(dong)(dong)受控這一特點出(chu)發的,故稱為“限(xian)動(dong)(dong)芯(xin)棒(bang)連軋(ya)管(guan)工藝”,后(hou)者是從Calmes 取名的“Multi-stand pilger mill”中“Pilger”變(bian)以“Pipe”演變(bian)而來的。由(you)于(yu)這一歷史原(yuan)因,這種軋(ya)機簡稱為 MPM軋(ya)機,而不是RMM.

采用這種工藝軋管,連軋不(bu)銹鋼管外徑最大可達406mm(16英寸),最佳尺寸為339.3mm(13 3/8英寸)。該工藝的實質是:在整個軋制過程中,控制芯棒運動速度,使其保持恒定;借助于脫管機,在軋制過程結束時,將芯棒從荒管中抽出,使其與芯棒裝置一起返回。

1. MPM工藝設備特征(zheng)

a. MPM軋機的特征(zheng)

MPM軋(ya)機(ji)采用機(ji)械(xie)限(xian)(xian)動(dong)(dong)式芯(xin)棒(bang)(bang)(bang)速(su)度(du)控制裝置,芯(xin)棒(bang)(bang)(bang)的(de)快速(su)動(dong)(dong)作(zuo)(穿心棒(bang)(bang)(bang)、抽芯(xin)棒(bang)(bang)(bang))及限(xian)(xian)動(dong)(dong)動(dong)(dong)作(zuo)(軋(ya)制時(shi)控制芯(xin)棒(bang)(bang)(bang)速(su)度(du))靠36m長的(de)大齒(chi)(chi)條(tiao)來實現(xian)。快速(su)動(dong)(dong)作(zuo)由兩(liang)臺500kW直(zhi)流電(dian)機(ji)分(fen)別驅動(dong)(dong)兩(liang)個(ge)齒(chi)(chi)輪(lun),從齒(chi)(chi)條(tiao)的(de)上(shang)下(xia)側(ce)帶動(dong)(dong)齒(chi)(chi)條(tiao)運(yun)(yun)動(dong)(dong)。限(xian)(xian)動(dong)(dong)動(dong)(dong)作(zuo)時(shi),由8個(ge)齒(chi)(chi)輪(lun)(上(shang)下(xia)各4個(ge))從齒(chi)(chi)條(tiao)的(de)上(shang)下(xia)側(ce)帶動(dong)(dong)齒(chi)(chi)條(tiao)運(yun)(yun)動(dong)(dong),每個(ge)齒(chi)(chi)輪(lun)均由1臺110kW直(zhi)流電(dian)機(ji)單獨傳動(dong)(dong)。芯(xin)棒(bang)(bang)(bang)運(yun)(yun)動(dong)(dong)方式的(de)改變依靠氣動(dong)(dong)離合器分(fen)別接通或脫開相(xiang)應的(de)齒(chi)(chi)輪(lun)來實現(xian)。芯(xin)棒(bang)(bang)(bang)的(de)快速(su)行程速(su)度(du)為6m/s,限(xian)(xian)動(dong)(dong)速(su)度(du)為0.2~0.5m/s,限(xian)(xian)動(dong)(dong)工(gong)作(zuo)行程為5.0~5.2m.

在(zai)Dalmine公(gong)司進(jin)行試驗時,芯棒(bang)的(de)運(yun)(yun)動(dong)速(su)度(du)采用液(ye)壓(ya)控制。但因(yin)液(ye)壓(ya)系統控制芯棒(bang)速(su)度(du)不夠穩定,有芯棒(bang)斷續運(yun)(yun)動(dong)的(de)情況(kuang),隨(sui)后改為齒輪齒條傳動(dong)的(de)機(ji)械系統。

MPM的軋輥孔型采用比普通連軋機(ji)開(kai)口(kou)角(jiao)稍小的封閉式圓(yuan)孔(帶弧形開(kai)口(kou)),可(ke)以采用較大的伸(shen)長(chang)率。

b. 脫管機的特征

MPM的(de)(de)(de)脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)機(ji)(ji)與(yu)(yu)(yu)二輥(gun)式(shi)定徑(jing)(jing)機(ji)(ji)相(xiang)同(tong)(tong),由(you)于MPM主軋(ya)(ya)機(ji)(ji)的(de)(de)(de)第(di)七、八機(ji)(ji)架的(de)(de)(de)壓下量(liang)很小,僅靠第(di)七、八機(ji)(ji)架軋(ya)(ya)輥(gun)的(de)(de)(de)作用無法推送管(guan)(guan)(guan)子前進和使(shi)管(guan)(guan)(guan)子從芯棒前端(duan)脫(tuo)(tuo)(tuo)出,故在MPM工藝(yi)中設置幾(ji)架脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)機(ji)(ji),起脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)和定徑(jing)(jing)的(de)(de)(de)作用。脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)機(ji)(ji)的(de)(de)(de)軋(ya)(ya)輥(gun)直(zhi)徑(jing)(jing)為720~850mm,輥(gun)身長(chang)420mm,第(di)一(yi)、三架由(you)1臺450kW的(de)(de)(de)直(zhi)流電(dian)機(ji)(ji)驅動(dong),而(er)第(di)二架則單獨由(you)1臺同(tong)(tong)型號電(dian)機(ji)(ji)驅動(dong)。脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)速度必(bi)須按連(lian)軋(ya)(ya)原則確定,并與(yu)(yu)(yu)MPM軋(ya)(ya)機(ji)(ji)的(de)(de)(de)第(di)八機(ji)(ji)架保持電(dian)氣連(lian)鎖。脫(tuo)(tuo)(tuo)管(guan)(guan)(guan)機(ji)(ji)的(de)(de)(de)減(jian)徑(jing)(jing)率為3.5%~4.6%,孔型與(yu)(yu)(yu)一(yi)般二輥(gun)式(shi)定徑(jing)(jing)直(zhi)機(ji)(ji)相(xiang)同(tong)(tong)。

c. MPM工藝的芯棒(bang)運(yun)動特征

軋(ya)(ya)(ya)制(zhi)(zhi)過程(cheng)中(zhong),要控制(zhi)(zhi)芯(xin)(xin)棒的(de)速度(du)(du),使(shi)其(qi)處于恒定(ding)狀態。雖然(ran)芯(xin)(xin)棒也隨(sui)管子(zi)前進,但其(qi)前進速度(du)(du)應遠(yuan)小于管子(zi)的(de)速度(du)(du),軋(ya)(ya)(ya)制(zhi)(zhi)結束(shu)后(hou)被抽出返回。軋(ya)(ya)(ya)制(zhi)(zhi)28m長的(de)管子(zi)時,芯(xin)(xin)棒長度(du)(du)為12m.芯(xin)(xin)棒為中(zhong)空水冷芯(xin)(xin)棒,軋(ya)(ya)(ya)制(zhi)(zhi)結束(shu)后(hou),芯(xin)(xin)棒溫度(du)(du)為400℃,需要采(cai)用內外噴水使(shi)之均勻冷卻。

2. 限動芯棒(bang)連軋管工(gong)藝技術發展的4個階(jie)段

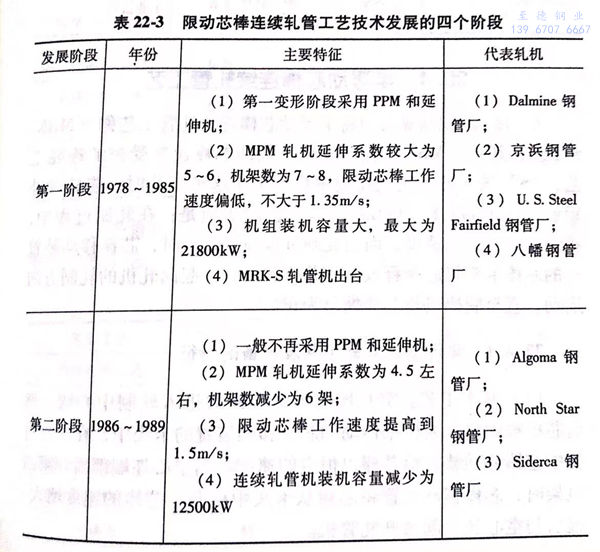

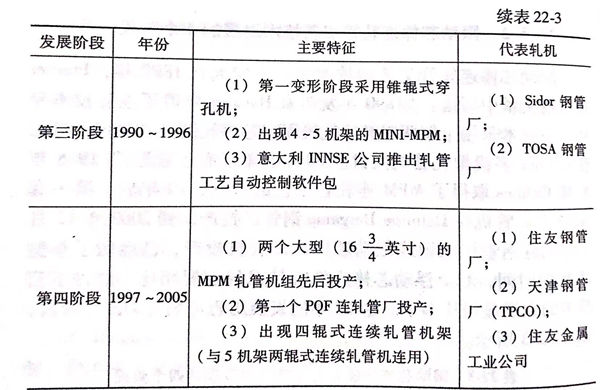

不(bu)銹鋼(gang)(gang)管(guan)限(xian)動(dong)芯棒(bang)連軋(ya)管(guan)工藝(yi)的(de)(de)技(ji)術(shu)發(fa)(fa)展(zhan)(zhan)(zhan)史應溯自1890年,Pfeiffer在一(yi)篇文章中寫道:“1890年發(fa)(fa)明家Heckert 申(shen)請了連軋(ya)技(ji)術(shu)專利(li),該技(ji)術(shu)采用十架兩(liang)輥高速(su)軋(ya)機(ji)固(gu)定芯棒(bang)軋(ya)制空心管(guan)坯(pi)。可(ke)見(jian)在Calmes 多(duo)(duo)機(ji)架軋(ya)管(guan)機(ji)問世前(qian)80年,就已有了雛形。”1968年A.H.Calmes 取(qu)得了MPM連軋(ya)管(guan)工藝(yi)的(de)(de)權利(li),10年后,第一(yi)套MPM連軋(ya)管(guan)機(ji)在Dalmine Bergamo 鋼(gang)(gang)管(guan)廠投產,到2003年12月天津無縫不(bu)銹鋼(gang)(gang)管(guan)廠三輥式限(xian)動(dong)芯棒(bang)連軋(ya)管(guan)機(ji)投產,已經歷(li)了整(zheng)整(zheng)25年的(de)(de)時間,和全浮動(dong)芯棒(bang)連軋(ya)管(guan)技(ji)術(shu)的(de)(de)發(fa)(fa)展(zhan)(zhan)(zhan)相比,這(zhe)種工藝(yi)技(ji)術(shu)的(de)(de)發(fa)(fa)展(zhan)(zhan)(zhan)顯(xian)得快多(duo)(duo)了。這(zhe)25年的(de)(de)發(fa)(fa)展(zhan)(zhan)(zhan)歷(li)程可(ke)劃分為四(si)個階段,如表22-3所示。