首先想了解不銹鋼沖壓、彎曲和連續沖裁加工工藝,必須要知道以下幾點:

a. 極限拉深比--拉深加工時,相對于容器直徑d可能拉深的最大原料板直徑為Dmax時,Dmax/d則稱為極限拉深比(LDR).

b. 平均r值--塑性(xing)(xing)為異(yi)向性(xing)(xing)的(de)(de)材料(liao)深(shen)(shen)拉深(shen)(shen)成(cheng)形特性(xing)(xing)評價(jia)的(de)(de)重要指標。鐵素體(ti)系(xi)列不(bu)銹鋼中,其(qi)平均r值越大(da),其(qi)極限(xian)拉深(shen)(shen)比就(jiu)越高。

c. 拉(la)深皺(zhou)折-鐵(tie)素體(ti)系列不銹(xiu)鋼在(zai)(zai)沖(chong)床上進行深拉(la)深加工時,在(zai)(zai)其表面上容易(yi)產生凹凸不平(ping)的皺(zhou)折。可認為是(shi)組合結構不同而引(yin)起的塑性(xing)異向性(xing)。

d. 時效性(xing)斷裂-奧氏體系列不銹(xiu)鋼(gang)SUS304等準穩(wen)定型(xing)奧氏體系列不銹(xiu)鋼(gang),在加(jia)工后有發(fa)生時效性(xing)裂紋的現象。它與晶界晶粒無關。一(yi)般認為是由(you)于(yu)加(jia)工感應而引(yin)起的馬(ma)氏體、氫和(he)殘余應力所致。

1. 沖壓加(jia)工

沖(chong)壓(ya)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)行業是(shi)家(jia)庭(ting)式作坊(fang)工(gong)(gong)(gong)(gong)(gong)業的(de)(de)代表性(xing)產(chan)業,多是(shi)從單獨一個(ge)一個(ge)地(di)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)西餐具(ju)、器(qi)皿(min)等所(suo)謂的(de)(de)“洋(yang)人筷(kuai)子”等開(kai)始,發展到(dao)餐飲(yin)業的(de)(de)廚房(fang)用(yong)(yong)具(ju)以(yi)及(ji)(ji)廚房(fang)中(zhong)所(suo)使(shi)(shi)用(yong)(yong)的(de)(de)水(shui)槽、洗(xi)滌(di)盆(pen)、深(shen)(shen)拉(la)(la)(la)深(shen)(shen)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)的(de)(de)澡(zao)盆(pen)以(yi)及(ji)(ji)汽車、電機(ji)領域中(zhong)的(de)(de)零(ling)部件等。主要工(gong)(gong)(gong)(gong)(gong)藝(yi)方法是(shi)采用(yong)(yong)剪切、沖(chong)孔(kong)、拉(la)(la)(la)深(shen)(shen)等進行連續加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)。洋(yang)餐具(ju)、器(qi)皿(min)和鍋的(de)(de)沖(chong)壓(ya)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong),基本上是(shi)屬于圓筒拉(la)(la)(la)深(shen)(shen)制(zhi)成。原(yuan)材料板直(zhi)(zhi)徑D對容器(qi)(產(chan)品(pin)(pin))直(zhi)(zhi)徑d之比(bi),D/d稱為(wei)拉(la)(la)(la)深(shen)(shen)比(bi)。以(yi)可能拉(la)(la)(la)深(shen)(shen)的(de)(de)最大原(yuan)材料板直(zhi)(zhi)徑為(wei)Dmax時,則(ze)Dmax/d稱為(wei)極限拉(la)(la)(la)深(shen)(shen)比(bi)(LDR: Limiting Drawing Ratio)作為(wei)衡量加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)性(xing)的(de)(de)指標。不(bu)(bu)銹(xiu)鋼(gang)產(chan)品(pin)(pin)得以(yi)大幅度(du)的(de)(de)增加(jia)(jia)(jia)需求與沖(chong)壓(ya)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)技(ji)(ji)術的(de)(de)發展有很大關系(xi)(xi)。不(bu)(bu)銹(xiu)鋼(gang)產(chan)品(pin)(pin)生(sheng)產(chan)廠家(jia)在(zai)深(shen)(shen)拉(la)(la)(la)深(shen)(shen)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)等方面(mian),由于塑性(xing)加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)技(ji)(ji)術和材料技(ji)(ji)術的(de)(de)進展。使(shi)(shi)得鐵(tie)素(su)體(ti)系(xi)(xi)列(lie)不(bu)(bu)銹(xiu)鋼(gang)高加(jia)(jia)(jia)工(gong)(gong)(gong)(gong)(gong)性(xing)鋼(gang)種,已經(jing)產(chan)品(pin)(pin)化了。可以(yi)選定平均(jun)r值(zhi)在(zai)1.2~1.8,LDR為(wei)2.2~2.5的(de)(de)鋼(gang)種。

在不銹(xiu)(xiu)鋼制品的(de)沖壓加(jia)工(gong)中,如(ru)果使用奧氏體(ti)系(xi)列(lie)不銹(xiu)(xiu)鋼或鐵素體(ti)系(xi)列(lie)不銹(xiu)(xiu)鋼的(de)高加(jia)工(gong)性能鋼種(zhong)時,可(ke)以進(jin)行一定(ding)程度的(de)深(shen)拉深(shen)加(jia)工(gong)。奧氏體(ti)系(xi)列(lie)不銹(xiu)(xiu)鋼的(de)代表型鋼種(zhong) SUS 304(18Cr -18Ni),因為它(ta)的(de)LDR為2.5,可(ke)以進(jin)行相對較大的(de)深(shen)拉深(shen)加(jia)工(gong)。

但(dan)由于加工硬(ying)化傾向(xiang)大而急劇地增加了加工難(nan)度,有時(shi)竟發生裂(lie)(lie)紋或斷裂(lie)(lie)。為此,沖(chong)壓廠家(jia)就(jiu)在(zai)中間(jian)加上一(yi)道(dao)熱處理工序之后(hou)再進行深(shen)拉(la)深(shen)加工。還必須注(zhu)意,奧氏體(ti)系列不銹鋼(gang)的奧氏體(ti)穩(wen)定度低的鋼(gang)種經過(guo)拉(la)深(shen)后(hou),有可(ke)能(neng)發生時(shi)效斷裂(lie)(lie)現象。

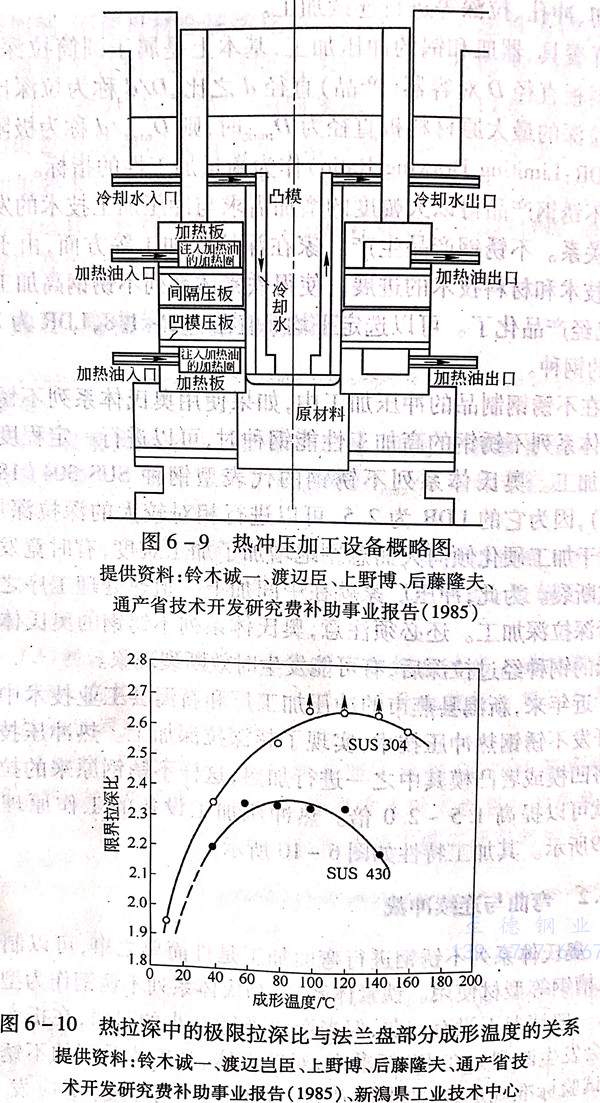

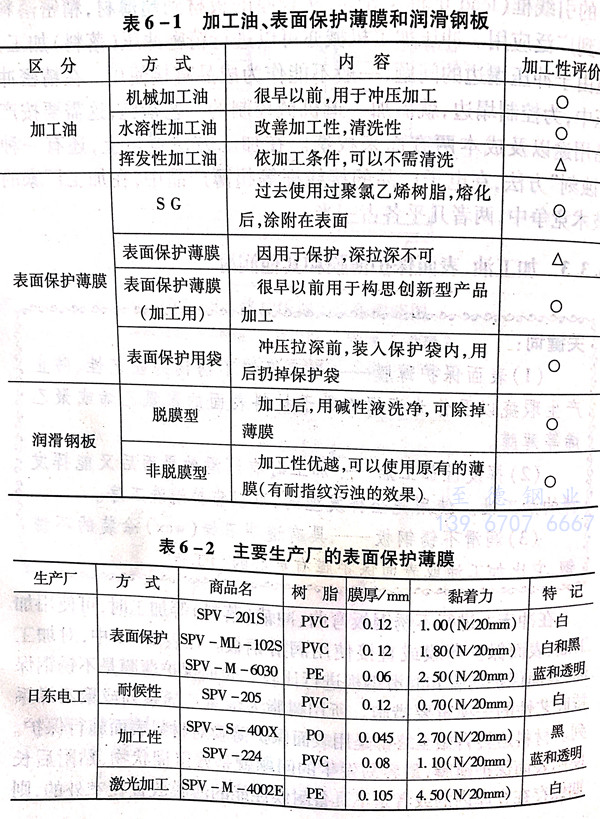

近年來,新(xin)潟(xi)縣燕(yan)市的沖壓加(jia)(jia)工(gong)(gong)廠和(he)新(xin)鴻縣工(gong)(gong)業技術中心共同開(kai)發(fa)不銹鋼熱(re)沖壓技術,實現了超深拉深加(jia)(jia)工(gong)(gong)。熱(re)沖壓技術就是(shi)將凹模(mo)或者凸模(mo)其中之(zhi)一進行加(jia)(jia)熱(re),這樣不銹鋼原來的拉深程度(du)就可以(yi)提高1.5~2.0倍。熱(re)沖壓加(jia)(jia)工(gong)(gong)設備的工(gong)(gong)作(zuo)原理如圖6-9所(suo)示(shi)。其加(jia)(jia)工(gong)(gong)特性如圖6-10所(suo)示(shi)。

2. 彎曲(qu)與連續沖裁

奧氏(shi)(shi)體(ti)(ti)系(xi)列(lie)不(bu)銹(xiu)鋼(gang)(gang)進行彎(wan)曲(qu)(qu)加(jia)(jia)工(gong)是件(jian)簡單(dan)之事(shi),可以(yi)(yi)制作角鋼(gang)(gang)、槽(cao)鋼(gang)(gang)等(deng)型(xing)材(cai)使(shi)(shi)用(yong)(yong)(yong)。鐵(tie)素(su)體(ti)(ti)系(xi)列(lie),馬(ma)氏(shi)(shi)體(ti)(ti)系(xi)列(lie)不(bu)銹(xiu)鋼(gang)(gang)作為(wei)型(xing)材(cai)加(jia)(jia)工(gong),一(yi)(yi)般(ban)情況下(xia)沒有(you)問(wen)題,但當(dang)彎(wan)曲(qu)(qu)半(ban)徑(jing)R小的(de)(de)(de)時(shi)候(hou),在(zai)折(zhe)彎(wan)處有(you)時(shi)會發生斷(duan)裂。在(zai)JIS標準中(zhong),對(dui)鐵(tie)素(su)體(ti)(ti)、馬(ma)氏(shi)(shi)體(ti)(ti)系(xi)列(lie)的(de)(de)(de)不(bu)銹(xiu)鋼(gang)(gang)彎(wan)曲(qu)(qu)試(shi)驗標準規定,彎(wan)曲(qu)(qu)半(ban)徑(jing)R為(wei)1.0t(t為(wei)板材(cai)厚度(du))不(bu)應發生彎(wan)曲(qu)(qu)斷(duan)裂。還(huan)有(you),必須注意不(bu)銹(xiu)鋼(gang)(gang)彎(wan)曲(qu)(qu)加(jia)(jia)工(gong)回彈量(liang)大(da)的(de)(de)(de)特(te)點。落(luo)(luo)料(liao)(俗稱(cheng)(cheng)下(xia)料(liao))或(huo)稱(cheng)(cheng)為(wei)沖(chong)(chong)(chong)裁加(jia)(jia)工(gong),大(da)多數(shu)是采用(yong)(yong)(yong)沖(chong)(chong)(chong)床連續加(jia)(jia)工(gong)的(de)(de)(de)方(fang)式(shi),有(you)時(shi)在(zai)沖(chong)(chong)(chong)切(qie)斷(duan)面上,發生塌(ta)邊(bian)(bian)現象(xiang)(即沖(chong)(chong)(chong)切(qie)面與(yu)基(ji)準平面不(bu)垂(chui)直(zhi))。精密(mi)落(luo)(luo)料(liao)是從變壓(ya)(ya)(ya)器等(deng)使(shi)(shi)用(yong)(yong)(yong)疊(die)層的(de)(de)(de)電(dian)磁鋼(gang)(gang)板的(de)(de)(de)加(jia)(jia)工(gong)技(ji)術(shu)(shu)開(kai)展起來的(de)(de)(de)技(ji)術(shu)(shu),對(dui)粒(li)子加(jia)(jia)速器的(de)(de)(de)套環(collar)或(huo)電(dian)子零(ling)部(bu)件(jian)中(zhong)的(de)(de)(de)引線框(kuang)(lead frame)等(deng)等(deng),從較厚的(de)(de)(de)板材(cai)到超(chao)薄材(cai),精密(mi)落(luo)(luo)料(liao)得到廣泛應用(yong)(yong)(yong)。沖(chong)(chong)(chong)壓(ya)(ya)(ya)加(jia)(jia)工(gong)機械亦可以(yi)(yi)進行精密(mi)沖(chong)(chong)(chong)壓(ya)(ya)(ya)(落(luo)(luo)料(liao))加(jia)(jia)工(gong),但由于沖(chong)(chong)(chong)壓(ya)(ya)(ya)塌(ta)邊(bian)(bian)的(de)(de)(de)問(wen)題,一(yi)(yi)般(ban)不(bu)能作為(wei)成品直(zhi)接(jie)使(shi)(shi)用(yong)(yong)(yong)。在(zai)精密(mi)沖(chong)(chong)(chong)壓(ya)(ya)(ya)中(zhong),為(wei)控制塌(ta)邊(bian)(bian),就(jiu)需(xu)加(jia)(jia)一(yi)(yi)道機械控制的(de)(de)(de)工(gong)藝措施,這(zhe)需(xu)要按產(chan)(chan)品用(yong)(yong)(yong)途以(yi)(yi)及成本兩(liang)方(fang)面來權(quan)衡。在(zai)加(jia)(jia)工(gong)方(fang)法(fa)(fa)競(jing)爭上,還(huan)有(you)一(yi)(yi)種(zhong)“蝕刻(ke)”方(fang)法(fa)(fa),在(zai)電(dian)子產(chan)(chan)品的(de)(de)(de)接(jie)線框(kuang)等(deng)超(chao)薄產(chan)(chan)品中(zhong),在(zai)加(jia)(jia)工(gong)廠家的(de)(de)(de)技(ji)術(shu)(shu)競(jing)爭中(zhong),兩(liang)者幾乎各占一(yi)(yi)半(ban)。

3. 加工油、表面保護薄(bo)膜和(he)其他潤滑

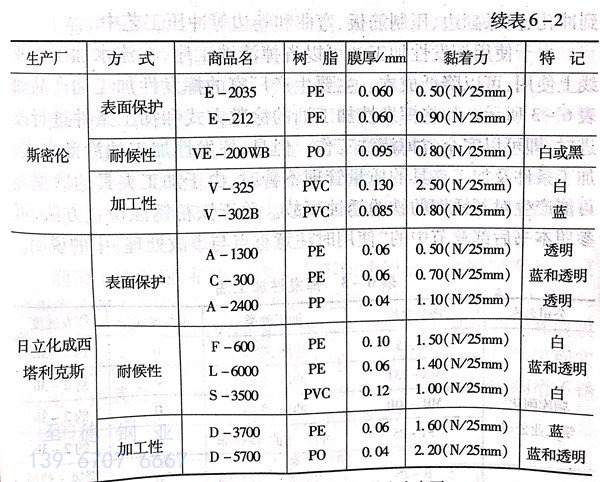

a. 表(biao)面保(bao)護薄膜-為了保(bao)持不銹鋼(gang)的(de)匠(jiang)藝(yi)性、防止產(chan)生瑕(xia)疵以及作為潤(run)滑而(er)敷于材料(liao)表(biao)面的(de)聚(ju)氯乙烯或(huo)聚(ju)乙烯等薄膜。

b. 揮(hui)發性加(jia)工(gong)油--加(jia)工(gong)時有潤滑(hua)效果而后(hou)又能揮(hui)發掉(diao)的加(jia)工(gong)油。使(shi)用完全揮(hui)發型的,可以(yi)省掉(diao)清洗工(gong)序(xu)。

c. 潤滑不銹鋼(gang)板-具有透明石蠟涂裝的不銹鋼(gang),它比加工(gong)油或表面保護膜有更好的加工(gong)性。

在(zai)(zai)沖床上進行(xing)不銹(xiu)鋼板彎曲、沖裁(落料)等(deng)加(jia)(jia)(jia)工(gong)(gong)時,可使用(yong)(yong)(yong)(yong)加(jia)(jia)(jia)工(gong)(gong)油、表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)或直接(jie)使用(yong)(yong)(yong)(yong)潤滑鋼板。在(zai)(zai)表(biao)(biao)(biao)(biao)6-1中,對(dui)加(jia)(jia)(jia)工(gong)(gong)油、表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)和潤滑鋼板進行(xing)比較。表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)是(shi)不銹(xiu)鋼保(bao)(bao)持匠藝性的(de)(de)(de)(de)一項重要(yao)措(cuo)施。所(suo)(suo)用(yong)(yong)(yong)(yong)樹脂(zhi)為聚氯乙烯系(xi)列或聚乙烯系(xi)列。材料運(yun)轉自始(shi)至終都是(shi)用(yong)(yong)(yong)(yong)表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)對(dui)材料表(biao)(biao)(biao)(biao)面(mian)施行(xing)保(bao)(bao)護(hu)。使用(yong)(yong)(yong)(yong)表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo),最(zui)容易(yi)(yi)發(fa)生的(de)(de)(de)(de)問題就(jiu)是(shi)殘留糊狀物(wu),貼附(fu)后(hou)長期保(bao)(bao)存在(zai)(zai)倉庫內的(de)(de)(de)(de)或者是(shi)不具備耐候性能的(de)(de)(de)(de)薄(bo)(bo)膜(mo)(mo)放(fang)置在(zai)(zai)室外的(de)(de)(de)(de),則(ze)容易(yi)(yi)發(fa)生損壞(huai)(huai)。表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)要(yao)根據(ju)用(yong)(yong)(yong)(yong)途(tu)和加(jia)(jia)(jia)工(gong)(gong)方法選定。主(zhu)要(yao)廠(chang)家生產的(de)(de)(de)(de)表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)性能及其有(you)關事項如表(biao)(biao)(biao)(biao)6-2所(suo)(suo)示(shi)。不使用(yong)(yong)(yong)(yong)表(biao)(biao)(biao)(biao)面(mian)保(bao)(bao)護(hu)薄(bo)(bo)膜(mo)(mo)時,一般(ban)情況下要(yao)使用(yong)(yong)(yong)(yong)加(jia)(jia)(jia)工(gong)(gong)油。當(dang)使用(yong)(yong)(yong)(yong)加(jia)(jia)(jia)工(gong)(gong)油加(jia)(jia)(jia)工(gong)(gong)后(hou),需進行(xing)洗凈(jing)。洗凈(jing)的(de)(de)(de)(de)方法有(you)多種(zhong),最(zui)近在(zai)(zai)保(bao)(bao)護(hu)地球環境問題當(dang)中,規定了保(bao)(bao)護(hu)環境條(tiao)例(li),對(dui)于(yu)破壞(huai)(huai)臭氧(yang)層的(de)(de)(de)(de)清洗劑做(zuo)出了限制(zhi)。

因(yin)(yin)此,當使用加工(gong)(gong)(gong)(gong)油(you)(you)時(shi),要(yao)(yao)(yao)考慮到(dao)洗(xi)凈(jing)和存放問(wen)題。在加工(gong)(gong)(gong)(gong)油(you)(you)選定方面,從(cong)前認(ren)為由(you)于不(bu)銹鋼(gang)(gang)硬度比(bi)普通(tong)鋼(gang)(gang)要(yao)(yao)(yao)高,加工(gong)(gong)(gong)(gong)不(bu)銹鋼(gang)(gang)比(bi)普通(tong)鋼(gang)(gang)困難,所(suo)以要(yao)(yao)(yao)選用有黏(nian)性(xing)(xing)的(de)加工(gong)(gong)(gong)(gong)油(you)(you)。具(ju)有黏(nian)性(xing)(xing)的(de)加工(gong)(gong)(gong)(gong)油(you)(you)往往是黏(nian)糊糊的(de),在加工(gong)(gong)(gong)(gong)過程(cheng)中不(bu)但(dan)變黑而且(qie)難以清(qing)洗(xi)。另外,其中多數(shu)情況下加入(ru)氯系列(lie)添(tian)加劑(ji)。因(yin)(yin)此,更有必(bi)要(yao)(yao)(yao)進行(xing)充分地清(qing)洗(xi)。近年(nian)來(lai),開發了許(xu)多水(shui)溶性(xing)(xing)加工(gong)(gong)(gong)(gong)油(you)(you),在深拉深等(deng)加工(gong)(gong)(gong)(gong)中,其潤(run)滑(hua)性(xing)(xing)堪比(bi)原用油(you)(you)性(xing)(xing)的(de)加工(gong)(gong)(gong)(gong)油(you)(you)。水(shui)溶性(xing)(xing)加工(gong)(gong)(gong)(gong)油(you)(you)比(bi)較(jiao)容易清(qing)洗(xi),應用效果很好。作為新技(ji)術,雖(sui)然(ran)加工(gong)(gong)(gong)(gong)條件受(shou)到(dao)某(mou)種程(cheng)度的(de)限制,免清(qing)洗(xi)的(de)揮發型(xing)加工(gong)(gong)(gong)(gong)油(you)(you)仍得到(dao)推(tui)廣。

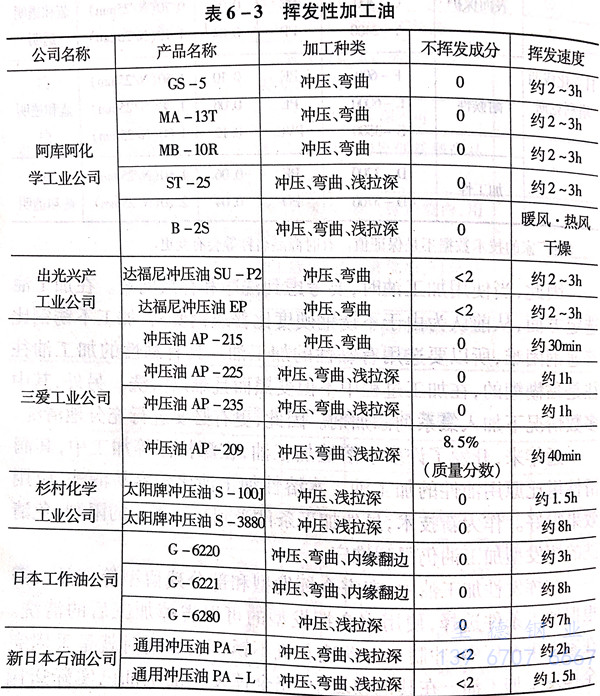

在揮發(fa)(fa)性(xing)加(jia)工(gong)(gong)油中(zhong),有完全(quan)揮發(fa)(fa)型(xing)和(he)部分殘留型(xing)等產品。需根據(ju)加(jia)工(gong)(gong)條件(jian)選擇,使用(yong)完全(quan)揮發(fa)(fa)型(xing)的(de)可(ke)以省掉加(jia)工(gong)(gong)后(hou)的(de)清洗(xi)。在家(jia)電生(sheng)產廠中(zhong),沖(chong)制全(quan)自動洗(xi)衣機(ji)不銹(xiu)鋼(gang)洗(xi)衣桶時就是采用(yong)完全(quan)揮發(fa)(fa)型(xing)加(jia)工(gong)(gong)油。在其(qi)他領(ling)域(yu)中(zhong),完全(quan)揮發(fa)(fa)型(xing)加(jia)工(gong)(gong)油已(yi)實(shi)際(ji)運(yun)用(yong)到沖(chong)孔、內緣翻邊、壓制筋板、彎曲和(he)卷邊等沖(chong)壓工(gong)(gong)藝中(zhong)。

由于(yu)使(shi)用(yong)揮發(fa)性(xing)加(jia)工(gong)(gong)(gong)油(you)可(ke)(ke)(ke)以(yi)省(sheng)掉(diao)清(qing)洗(xi)工(gong)(gong)(gong)序,在流水加(jia)工(gong)(gong)(gong)作(zuo)業線上使(shi)用(yong),可(ke)(ke)(ke)以(yi)降低成本。主要生(sheng)產廠家的(de)揮發(fa)性(xing)加(jia)工(gong)(gong)(gong)油(you)產品(pin)如表(biao)6-3所示。如將揮發(fa)性(xing)加(jia)工(gong)(gong)(gong)油(you)的(de)涂(tu)(tu)敷方式和加(jia)工(gong)(gong)(gong)條(tiao)件進行改進時,即可(ke)(ke)(ke)以(yi)完全省(sheng)掉(diao)清(qing)洗(xi)工(gong)(gong)(gong)作(zuo)。但是,揮發(fa)性(xing)加(jia)工(gong)(gong)(gong)油(you)涂(tu)(tu)敷方式、加(jia)工(gong)(gong)(gong)條(tiao)件及(ji)加(jia)工(gong)(gong)(gong)夾(jia)具的(de)質量管理不善時,由于(yu)加(jia)工(gong)(gong)(gong)夾(jia)具的(de)磨損等可(ke)(ke)(ke)能產生(sheng)對不銹鋼的(de)鐵(tie)(tie)粉銹蝕事故(gu)。關于(yu)鐵(tie)(tie)粉銹蝕檢(jian)查方法,可(ke)(ke)(ke)參(can)照本書(shu)后部章節中的(de)“使(shi)用(yong)時注(zhu)意重占日惠執處理”由的(de)說明。

先(xian)前在(zai)沖壓加(jia)工(gong)過程中使用加(jia)工(gong)油(you)。為了洗(xi)凈(jing)這些加(jia)工(gong)油(you)而使用了破壞臭氧層的三氯乙(yi)烷,三氯乙(yi)烯等。后(hou)來,洗(xi)凈(jing)方法(fa)改為堿性(xing)洗(xi)凈(jing)方法(fa)。在(zai)1995年,考慮(lv)到保護地球環境問題,開發(fa)了潤(run)(run)(run)滑(hua)(hua)不銹(xiu)(xiu)鋼(gang)(gang)(gang)板(ban)。在(zai)汽(qi)車、電機、燃(ran)氣(qi)器具領(ling)域中,積極推(tui)廣(guang)了省(sheng)掉清洗(xi)工(gong)序的潤(run)(run)(run)滑(hua)(hua)不銹(xiu)(xiu)鋼(gang)(gang)(gang)板(ban)。特別是(shi)在(zai)汽(qi)車領(ling)域中的排氣(qi)分支管的不銹(xiu)(xiu)鋼(gang)(gang)(gang)化過程中,實踐證(zheng)明,加(jia)工(gong)這種形狀復雜的工(gong)件,認為潤(run)(run)(run)滑(hua)(hua)不銹(xiu)(xiu)鋼(gang)(gang)(gang)板(ban)比(bi)以(yi)前使用潤(run)(run)(run)滑(hua)(hua)油(you)的加(jia)工(gong)性(xing)更(geng)優越(yue)。所以(yi),潤(run)(run)(run)滑(hua)(hua)不銹(xiu)(xiu)鋼(gang)(gang)(gang)板(ban)的需要(yao)量大幅度增加(jia)。

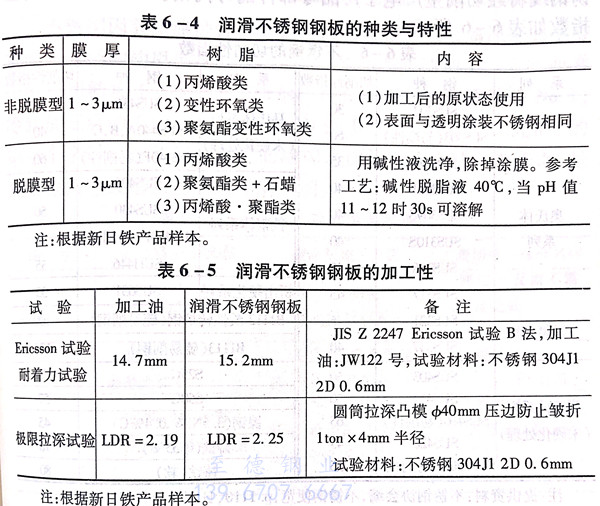

潤滑(hua)不(bu)(bu)銹(xiu)(xiu)鋼板,根據用(yong)途亦有不(bu)(bu)涂薄膜(mo)(mo)的(de)。非脫(tuo)膜(mo)(mo)型(xing)和(he)脫(tuo)膜(mo)(mo)型(xing)兩(liang)類已經(jing)產品化了。潤滑(hua)不(bu)(bu)銹(xiu)(xiu)鋼板種類和(he)特性如表6-4所(suo)示。在建(jian)筑材料領域中,使用(yong)潤滑(hua)不(bu)(bu)銹(xiu)(xiu)鋼板做屋(wu)頂時,非脫(tuo)膜(mo)(mo)型(xing)和(he)脫(tuo)膜(mo)(mo)型(xing)一樣(yang),其薄膜(mo)(mo)經(jing)過1~2年的(de)紫外線照(zhao)射就消失了。作(zuo)為工(gong)程實(shi)例,用(yong)于西武百貨大樓和(he)福岡機場候機大廳。實(shi)踐證明,潤滑(hua)不(bu)(bu)銹(xiu)(xiu)鋼板的(de)加(jia)工(gong)性比加(jia)工(gong)油還(huan)要優越,見表6-5。

不(bu)銹(xiu)鋼(gang)板(ban)生產廠家的潤滑不(bu)銹(xiu)鋼(gang)板(ban)產品,在透(tou)明(ming)涂裝不(bu)銹(xiu)鋼(gang)項(xiang)目中(zhong)有介紹。